· Cardiac

· Vascular

· Orthopedic, Spinal and Extremity

· Neurostimulation

· Special device markets, including cochlear and ophthalmic implants

Precision Machining

Specialized in CNC micro-machining and assembly, scratch-free surface finishes, electrode coatings,customer alloy development. Pulse Technologies directs all of its efforts to the implantable medical device market, focusing on these sectors:

Application

· Cardiac

· Vascular

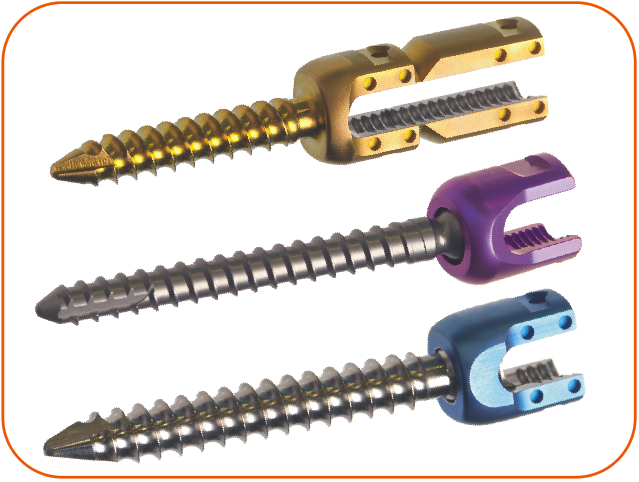

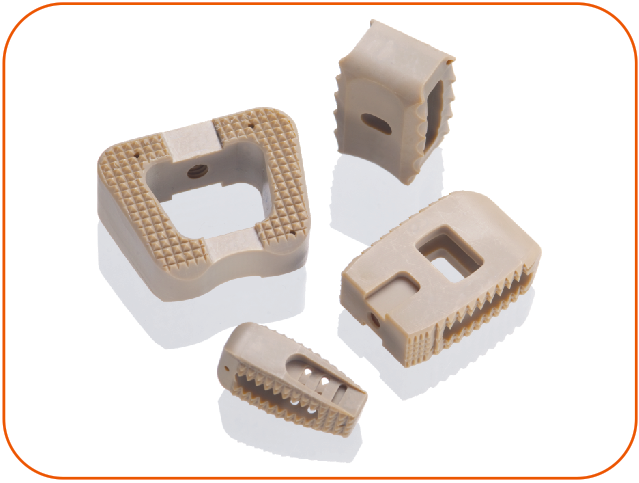

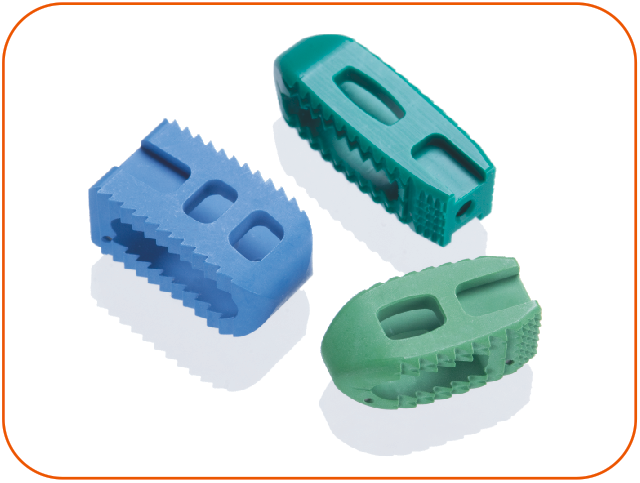

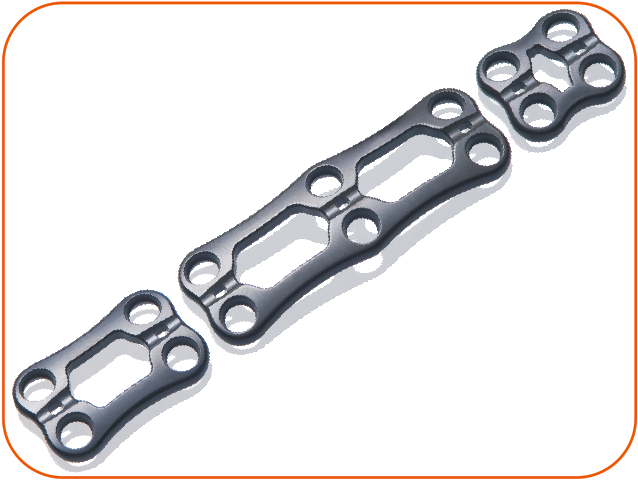

· Orthopedic, Spinal and Extremity

· Neurostimulation

· Special device markets, including cochlear and ophthalmic implants

Material

· Precious Metals: Platinum, iridium, tantalum, gold, silver, palladium

· Metals: Titanium, stainless steel, MP35N, CoCr, plus exotics

· Plastics: PEEK, HDPE, Udel, Radel, UHMWPE, Delrin, Polycarbonate

A wide range of contract manufacturing capabilities

| · Swiss Screw Machining | · Wire coiling |

| · Milling | · Precision Finishing and Marking |

| · Scratch-free Surface Finish | · Titanium Anodizing |

| · Custom Alloy Development | · Electrical Discharge machining |

| · Pulse Advanced Coating Technology(PACT) | · Metallurgy and Metrology Laboratory |

| · Laser Machining | · PVD Coating |

| · Laser Welding | · Nano Texturing |

| · Laser Texturing | · Heat Treating, Grinding & Irradiation |

Swiss Screw Machining

· Up to 11 axis micromachining

· Multi-spindle machine for high volume production

· Thread whirling capability

· Contour milling

· Outside diameters as small as .012”(0.305mm)

· Small hole diameters to .006”(0.152mm)

· Thin wall machining to .0015”(0.038mm)

Milling

· Small intricate part and feature machining on 3-5 axis machines

· High capacity multi-pallet mill and mill/turn machines up to 7 axis

· Tolerance and positions to .0002”(0.005mm)

Scratch-free Surface Finish

· Automated, non-contact surface finishing for metallic parts

· High capacity multi-pallet mill and mill/turn machines up to 7 axis

· Tolerance and positions to .0002”(0.005mm)

· Applications: Hemolytic pumps/ tubes, anti-clotting surfaces

Advanced Alloys – Ti

· Titanium based alloy for implants

· 30-40% stronger than Grade 23 (Grade 5 ELI, Ti6Al4V)

· Does not contain irritants such as Al and V

· Applications: Orthopedic screw and plates, critical medical device implants

Advanced Alloys – PA-16

· Radiopaque alloy for use in medical implants

· No precious metal/ stable-price solution to Pt alloys

· Applications: Medical electrodes, radiopaque marking

Pulse Advanced Coating Technology(PACT)

· A specialized coating for stimulation and sensing electrodes

· Electrode size can be reduced by 50%

· Applications: Tissue Stimulation (cardiac pacing, neurostimulation etc.), biorhythm Sensing

Laser Machining

· 4 axis machining

· Ability to cut tube as well as sheet stock with reduced slag and re-case

· 0.001" (0.025mm) spot laser creates extremely precise holes and notches as thin as one-third of a human hair

· Accuracy of +/-.00004”(0.001mm)

· Extremely clean final product with negligible slag

Laser Welding

· Weld spot as small as .004”(0.100mm)

· Weld seams as small as .002”(0.050mm)

· Micro-welding of fine wire down to .002”(0.050mm) diameter

· Similar and dissimilar welding applications

· Can weld most metals-precious metals,SS,titanium

· Ability to control weld overlap

Titanium Anodizing

· State-of-the-art in-line automated color titanium anodizer for precise color control

· Part masking capabilities

Laser Texturing

· Controlled surface roughness for improved bonding strength

· Applications: Metal part to polymer cannula assembly, PEEK to polymer assembly

Electrical Discharge machining

· Wire and Ram capabilities: .002-.012”(0.0500-.305mm)wire diameters

· Holes to .004”(0.102mm)

Wire coiling

· Wire forming and coiling for small diameter wire

· Ability to make coils with variations in pitch and diameter (within coil)

· Automated precision grinding of coil tip

· Applications: Active fixation electrodes, Medical spring

Precision Finishing and Marking

· Laser marking

· Micro--blasting

· Deburring

· Tumbling

· Electro-polishing

· Passivation

Metallurgy and Metrology Laboratory

· Contact and optical coordinate measuring machine

· Scanning electron microscope

· Laser micrometers

Nano Texturing

· Ultrafast high energy surface modification

· Nano structures are created that increase the surface area similar to TiN

· No coating eliminates the need for adhesion validation and testing

· Base material is transformed to form structure – no loss of mechanical properties

· Applications: Active fixation electrodes (helices), Proximal rings, Distal tips

0.001" (0.025mm) spot laser creates extremely precise holes and notches as thin as one-third of a human hair

Ability to cut sheet stock as well as tube

Extremely clean final product with negligible slag