· Drug Delivery

· Stent Delivery

· Electrical Insulation

· Variable-Stiffness Shafts

· Renal denervation

· Neuro embolization

· Cryoablation

· Balloon sinuplasty

· Transcatheter aortic valve implantation (TAVI)

· Endovascular AAA repair

· Balloon occlusion

· Hypothermic cooling

· Ablation

· Lumbar discectomy

· Balloon angioplasty

· Esophageal dilation

· Atherectomy

· Balloon carpal tunnelplasty

· Neuromodulation

· Laser lithotripsy

· Cardiac pacing

· Kyphoplasty

· Perfusion

· and a variety of minimally invasive applications

Nordson MEDICAL is a global expert in the design, development, and manufacturing of complex medical devices and component technologies. We serve interventional, surgical, and specialized markets as the engine of innovations that save or enhance patients' lives.

Component & Technologies

· Medical BalloonsHeat Shrink Tubing

· Heat Shrink Tubing

· Polyimide Tubing

· PTFE Liner Tubing

· Extruded Tubing

· Reinforced Tubing

· Nitinol Components

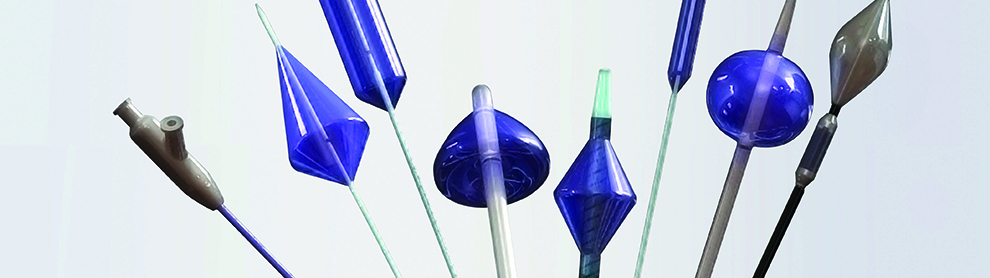

Nordson MEDICAL is the market leader in complex medical balloon design, development, and manufacturing. Our pioneering Advanced Polymers team was the first to manufacture and supply medical balloons to the medical device industry. Our medical balloon expertise is unmatched, with:

· 25+ years of experience

· 1 million+ balloons manufactured annually

· > 300 custom balloons designed annually

Benefits of Nordson MEDICAL’s Balloon Offerings

· Highest quality in the industry

· Extensive stock inventory of balloons available immediately

· Experienced engineers developing cutting edge solutions including:

· Multi-lumen balloons

· Braid-reinforced balloons for ultra-high strength

· Lead times as short as 2 weeks

Medical Balloon Types and Specifications

| Non-compliant Dilatation Balloons | |

| Characteristics | Ultrahigh strength, thin walls |

| Materials | PET |

| Compliance Range | 0%–10% (typical) |

| Color | Optically clear or colored |

| Light transmission | Transmits light over very broad spectrum including Nd:YAG lasers |

| Sizes | Diameter: 0.5 mm–80 mm; Length: Virtually any (15" max) |

| Burst pressures | 15 psi–400 psi (1atm–27 atm) |

| Coatings available | Yes |

| Semi-compliant Dilatation Balloons | |

| Characteristics | High strength, thin walls |

| Materials | PET, Nylon, Polyurethane, other thermoplastic elastomers |

| Compliance Range | 10%–20% (typical) |

| Sizes | Diameter: 0.5 mm–50 mm; Length: Virtually any (15" max) |

| Burst pressures | 15 psi–375 psi (1 atm–25.5 atm) |

| Coatings available | Yes |

| Compliant Balloons | |

| Characteristics | Low pressure, thin and thick walls |

| Materials | Polyurethane, Nylon elastomers, and other thermoplastic elastomers |

| Compliance Range | 20%–200% or more |

| Sizes | Diameter: 0.5 mm–80 mm; Length: Virtually any (15" max) |

| Burst pressures | 0 psi–30 psi (0 atm–2 atm); Balloons can be designed for volume |

| Coatings available | Yes |

Medical Balloon Shapes

|  |  |  |

| Standard Balloon | Conical Balloon | Square Balloon | Spherical Balloon |

|  |  |  |

| Elliptical Balloon | Conical / Square Balloon | Long Conical / Square Balloon | Conical / Spherical Balloon |

|  |  |  |

| Long Spherical Balloon | Tapered Balloon | Dog Bone Balloon | Stepped Balloon |

|  |  | |

| Offset Balloon | Conical / Offset Balloon | Your Design |

Standard Medical Balloon Ends

|  |  |

| Conical Sharp Corner | Conical Radius Corner | Square End |

|  |  |

| Spherical End | Offset Neck | Your Design |

Coatings

A wide variety of coatings can be added to the surface of a complex medical balloon to enhance or change its properties to meet new requirements, including:

· Lubricious coatings (hydrophilic and hydrophobic)

· Abrasion- and puncture-resistant coatings

· Tacky or high-friction coatings

· Conductive coatings

· Antithrombogenic coatings

· Drug-release coatings

· Reflective coatings

· Selective coatings

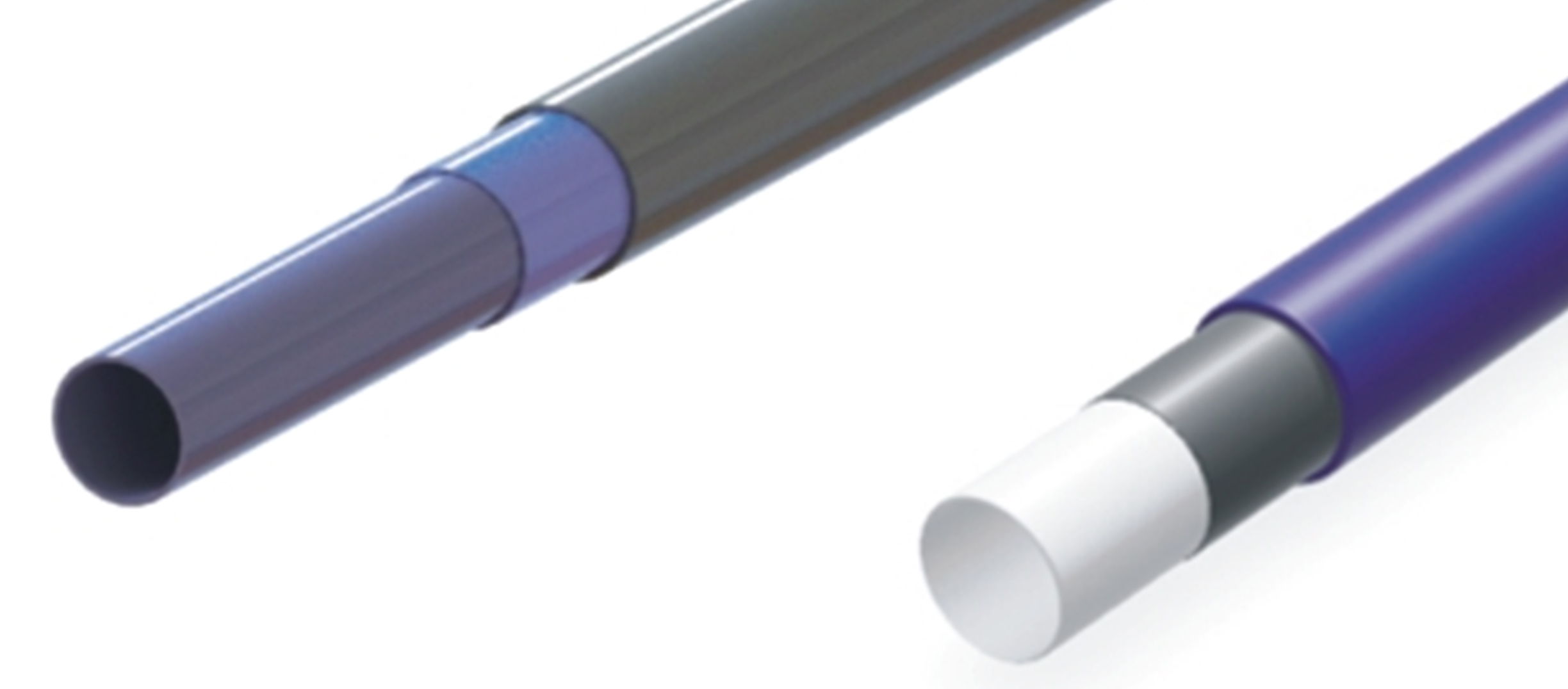

Polyester (PET) Heat Shrink Tubing

The world’s thinnest, smallest, & strongest heat shrink tubing. Nordson MEDICAL’s polyester (PET) heat shrink tubing is ultra-thin-walled, high-strength, optically clear or pigmented and heat shrinkable. This Vention Medical technology was developed specifically for the medical device industry, and has been at the leading edge of medical device tubing since its creation.

Characteristics

PET Heat Shrink Tubing is an extremely unique material with impressive characteristics including:

· Ultra-thin wall, ultra-high strength, and high dielectric strength

· Can be recovered at relatively low temperatures

· Axial shrinkage pulls components together

· Can be transformed into custom parts by drawing/shrinking onto a shaped mandrel(conical, square, triangular, etc.)

· Can be “heat-set” so that it is stable up to a rescribed temperature

· Can be printed for shaft marking/indicating

Applications

· Braid termination

· Insulation

· Encapsulation, bundling, and strain relief

· Masking for coating procedures

· Micro-hose clamps

· Tube joining (variable stiffness catheters)

· Balloon bonding

· Shaft lamination

· Tipping

· General reflow (RX ports, braided shaft lamination, etc).

Specifications

| Diameter range | 0.006” – 1.5” (0.15 – 38.1 mm) |

| Wall thickness range | 0.0001” – 0.004” (0.0025 – 0.10 mm) |

| Shrink ratios | 1.1:1 up to 3:1* |

| Tight fit is best | 15% gap or less** |

| Material melt temp | 473°F (245°C) |

| Recommended hot box range | 300°F to 450°F (149°C to 232°C) |

| Material Compatibility | PET releases easily from most common thermoplastics. However, some low-durometer urethanes tend to tack to the PET and may require a resting period (~1hr) or may not be compatible. Run test samples with these materials. |

| Tensile Strength | Very high tensile strength can be realized (>20,000 PSI) |

| Electrical Insulation | Good |

| Surface Finish | Ultra smooth, hard, glossy finish |

| Color/Clarity | Available in clear and a variety of opaque and transparent colors |

| Bondability | Can be bonded using a wide range of adhesives (surface treatment recommended) |

| Flex Fatigue | Very high flex fatigue properties |

| Biocompatibility | Meets USP Class VI and ISO 10993 requirements |

| Sterilization | Ethylene Oxide, Gamma Irradiation, E-Beam and Autoclave (repeat autoclaving is not recommended) |

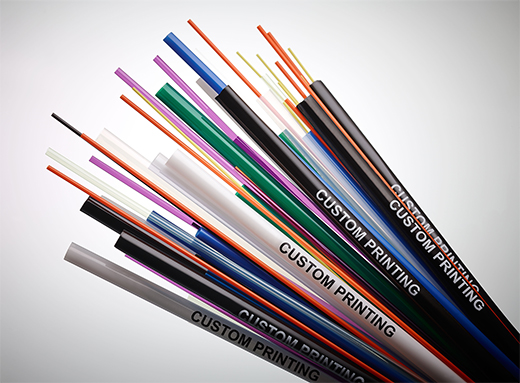

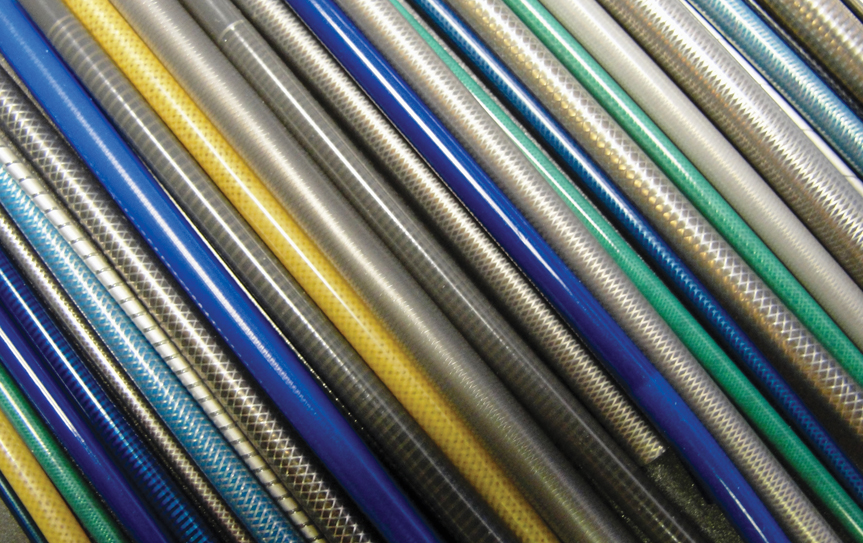

Medical Tubing

Nordson MEDICAL is a pioneer and innovator in the design, development, and manufacturing of medical tubing, with decades of experience. We have the broadest, most versatile medical tubing line in the industry. From simple medical tubing to complex, tight-tolerance extruded tubing in a wide range of materials including polyimide tubing, we can meet your needs.

· PolyimideTubing

· PTFE Liner Tubing

· Extruded Tubing

· Reinforced Tubing

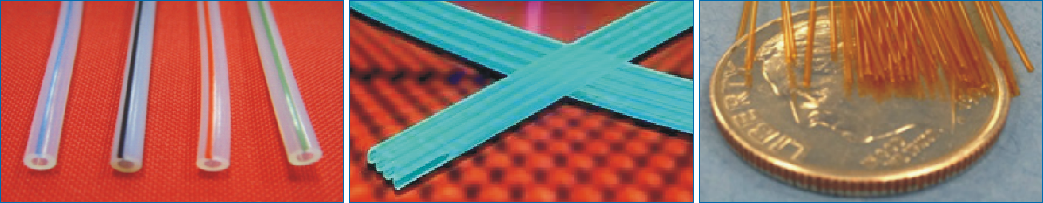

PolyimideTubing

Polyimide is a thermoset tubing material.

Features

· Very thin wall thickness

· Tight-tolerance inner and outer diameters

· Outstanding electrical insulation properties

· Stiffness and column strength as required

· Ability to withstand very high temperatures

· 81 different layering and custom composite configurations

Applications

· Cardiovascular, peripheral, and neurological catheters

· Urological retrieval devices

· Electrical insulation

· Fiber optics

· Intravascular drug delivery

· Gastrointestinal devices

Specifications

| ID Range | 0.004"–0.085" (0.102 mm–2.159 mm) |

| Wall Thickness Range | 0.0005"–0.0100" (0.0127 mm–0.2540 mm) |

| OD Tolerance | ±0.0002"–±0.0005" (±0.0051 mm–±0.0127 mm) |

| Length | Standard: 36"–55" |

| Maximum: 32' | |

| Custom Cutting: 0.020"–73.0" | |

| For tubing with at least 0.001" wall thickness and OD of 0.0125"–0.0770" | |

| Contact us to discuss cutting other tubing sizes | |

| Color | Amber (transparent) Can be produced in a variety of colors including black, green, yellow, red, and others |

| Printing | Can be printed using conventional techniques |

Material Properties

| Polymer Type | Thermoset |

| Tensile Strength | 20,000 psi min. |

| Elongation (@ Break) | 30% min |

| Modulus of Elasticity | 310 kpsi |

| Dielectric Strength | 4000 V/.001" |

| Moisture Absorption | 0.841 wt.% (24 hrs.) |

| Melting Temperature | N/A |

| Thermal Range | -269°C to 400°C |

| Thermal Conductivity | 0.471 W/m*K |

| Coefficient of Friction | 0.5 (dry, dynamic) |

Features of Thin-Wall Polyimide Tubing

· USP Class VI compliant

· Chemically inert

· Excellent chemical resistance

· Excellent torque transmission

· Excellent column strength

· Nonmelting

· Microsize IDs

· Transparent

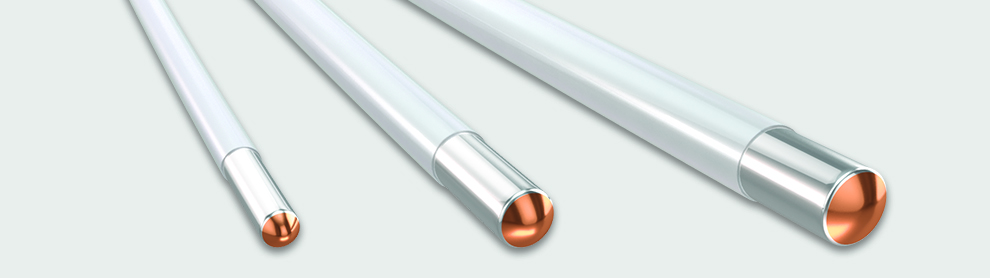

PTFE Liner Tubing

When your catheter assembly needs a lubricious inner layer, a PTFE liner is the ideal choice. But not all PTFE liner tubing is the same. We supply etched PTFE liners on solid, silver-plated, copper-core mandrels, which give you these advantages:

Advantages

· Thinner walls

· Our PTFE liners on mandrels are fabricated with a film-cast process similar to what we use for our polyimide tubing. Ultrathin liner tubing (as thin as 0.0005”, or 0.0127 mm) allows you to design thinner catheter walls.

· Time savings

· Sourcing PTFE liners on mandrels means you don’t have to stretch the liner onto another mandrel. This streamlines the assembly process and also allows you to:

o Maintain precise IDs

o Reduce risk of adhesion issues

PTFE has the lowest coefficient of friction of any polymer, making it a popular choice for catheter applications that require lubricity. It also features:

· Temperature and chemical resistance

· Biocompatibility

· Precise tolerances

· High dielectric strength

· Excellent insulative properties

Specifications

| Inner Diameter (ID) Range | 0.014"–0.096" (0.35 mm–2.4 mm) |

| Outer Diamter (OD) Range | 0.015"–0.099" (0.38 mm–2.5 mm) |

| Wall Thickness | 0.0005"–0.0015" (0.013 mm–0.038 mm) |

| Length | Custom cut or continuous-spooled lengths |

| Strike Layer Thickness | As thin as 0.0003” (0.0076 mm) |

| Strike Layer Materials | Nylon (11 and 12) |

| Pebax® (55D, 70D and 72D) | |

| Polyurethane (Tecoflex®) |

Extruded Tubing

Nordson MEDICAL has a long, successful track record of supplying high-precision, specialized extruded tubing to the medical device industry. A global partner with facilities around the world, we specialize in high-performance tubing for critical applications.

Single-Lumen Extruded Tubing Specifications

| Single Lumen | Single Lumen Ultrathin Wall | Single Lumen Microthin Wall | |

| OD Range | From 0.003" (0.076 mm) | 0.004"–0.120" (0.102 mm–3.048 mm) | 0.020"–1" (0.508 mm–25.4 mm) |

| OD Tolerance | From ± 0.0003" (± 0.008 mm) | From ± 0.0002" (± 0.005 mm) | From ± 0.0004" (± 0.001 mm) |

| Wall | From 0.001" (0.025 mm) | From 0.0005" (0.013 mm) | 0.00025"–0.003" (0.006 mm–0.08 mm) |

| Length | Standard: 62" (157 cm) Custom Cutting: · Maximum straight length: 96" o Longer lengths possible for some sizes · Minimum: 0.020" or less | ||

Typical Materials (Contact us for additional options) | ABS, Acetal, Arnitel, Bionate, Carbothane, Chronosil, EFEP, Elastollan, ETFE, EVA, EVAL, FEP, HDPE, Hytrel, Kynar PVDF, LDPE, LLDPE, Medalist, NEOFLONTM EFEP RP-5000, NEOFLONTM PFA AP-210, Nylon 11, Nylon 12, Nylon 6, Pebax® 35D, Pebax 45D, Pebax 55D, Pebax 63D, Pebax 70D, Pebax 72D, Pebax/EverGlide®, Pebax/Mobilize, Pebax/PEBASlide, Pebax/ProPell STM PEEK, Pellethane 55D, Pellethane 75D, PET, PFA, Polycarbonate, Polypropylene, Polysulfone, Primacor, PVC, Resin, Rezilient, Santoprene, SEBS, Tecoplast, Tecothane, Texin, Thermoplastic Polyimide | ||

| Printing | Can be printed using conventional techniques | ||

· 2–9 lumens for the passage of guidewires, catheters, fluids, and gasses

· Number of lumens depends on material and cross-sectional area

· Lumens can be shaped to meet user requirements

· Lumen can be contained within a round tube or other cross sections (oval, figure 8)

Specifications

| OD Range | 0.030" (0.8 mm) and up |

| OD Tolerance | From ± 0.001" (± 0.025 mm) |

| Lumen Diameter | 0.006" (0.152 mm) and up |

| Length | Standard: 62" (157 cm Custom Cutting:) · Maximum straight length: 96" o Longer lengths possible for some sizes · Minimum: 0.020" or less |

Typical Materials (Contact us for additional options) | Polyurethane, Pebax, PET, Nylon, Polypropylene, PEEK, Polycarbonate, HDPE, TPE |

| Printing | Can be printed using conventional techniques |

Coextruded Multilayer Extruded Tubing Specifications

| Up to 3 discrete layers | |

| OD Range | From 0.016" (0.410 mm) |

| OD Tolerance | From ± 0.00027" (± 0.007 mm) |

| Wall | From 0.0016" (0.041 mm) |

| Length | Standard: 62" (157 cm) Custom Cutting: · Maximum straight length: 96" o Longer lengths possible for some sizes · Minimum: 0.020" or less |

| Materials | Outer jacket: Polyurethane, Pebax, PET, Nylon, Polypropylene, HDPE, TPE Inner jacket: Polypropylene, HDPE, Polyurethane |

| Printing | Can be printed using conventional techniques |

Coextruded Striped Extruded Tubing Specifications

| OD Range | From 0.020" (0.508 mm) |

| OD Tolerance | From ± 0.00027" (± 0.007 mm) |

| Wall | From 0.0016" (0.04 mm) |

| Length | Standard: 62" (157 cm) Custom Cutting: · Maximum straight length: 96" o Longer lengths possible for some sizes · Minimum: 0.020" or less |

Typical Materials (Contact us for additional options) | Polyurethane, Pebax, Nylon, TPE Stripes: a range of radiopaque fillers |

| Printing | Can be printed using conventional techniques |

Coextruded Multilayer Tubing: Typical Configurations

| Coextruded Multilayer Component | Desired Primary Property on Inner Layer | Inner Layer Material | Desired Primary Property on Outer Layer | Outer Layer Material |

| PTA/PTCA Inner Tubing | Lubricity | HDPE | Bondable to adjacent device components | Nylon 12 |

| Infusion Tubing | Chemical inertness | HDPE | Flexibility | PVC |

| Tungsten-Polymer Marker Band | Radiopacity | 80% Tungsten-filled PUR | Smoothness | PUR |

| Implantable Central Venous Catheter | Flexibility | PUR | Antimicrobial | Silver ion-filled PUR |

| Coronary Implant Delivery System | Lubricity | HDPE | Bondable to adjacent device components | Pebax |

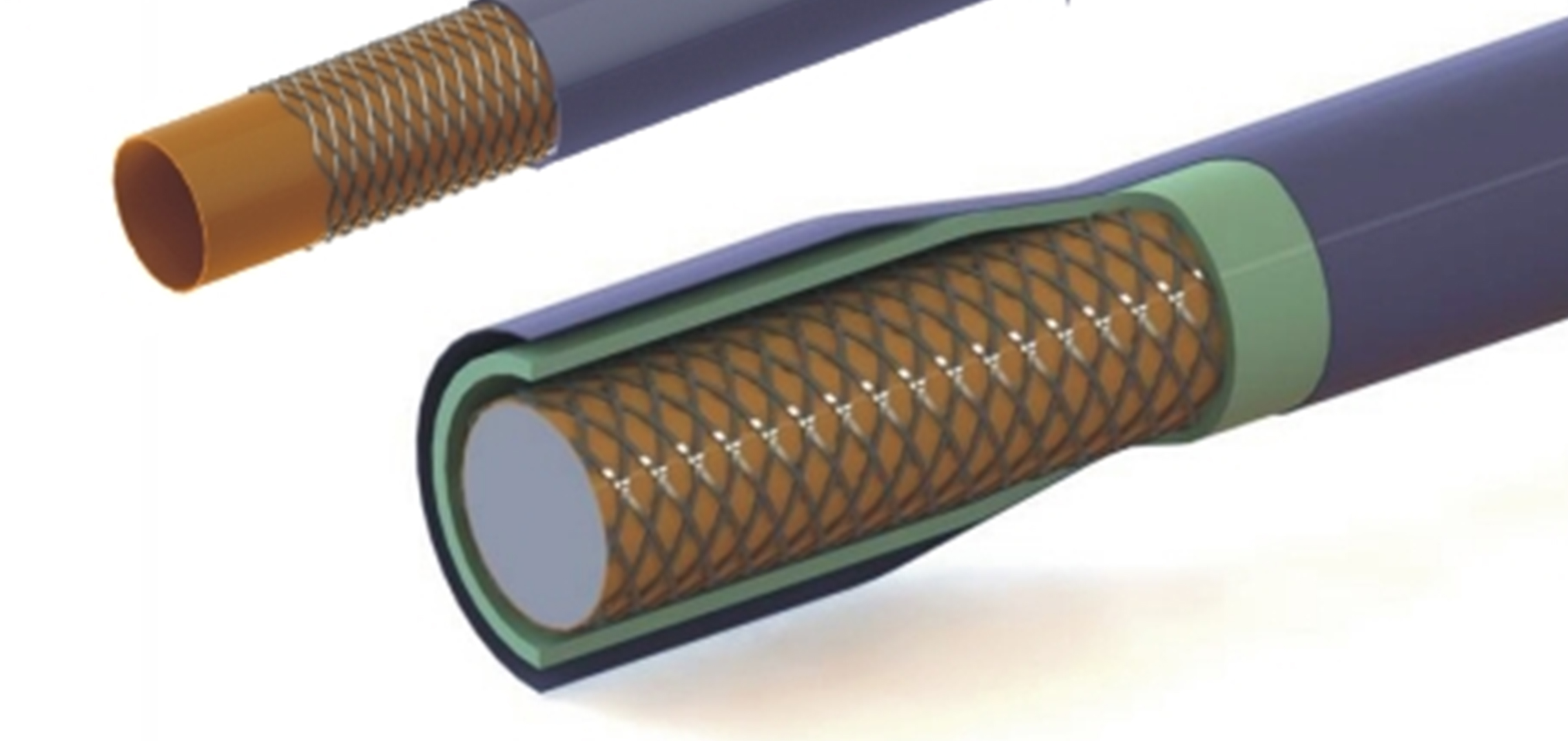

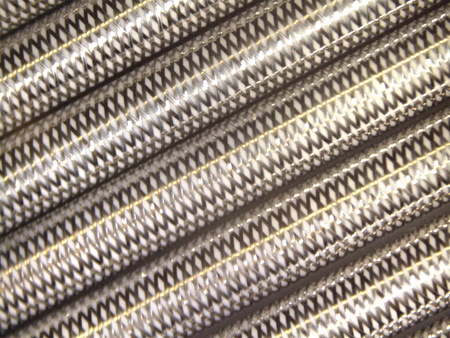

Custom Braid-Engineered Shaft Capabilities

| Minimum Inner Diameter | 0.004" (0.3F) |

| Maximum Outer Diameter | 0.420" (32F) |

| Liner Materials | PTFE, FEP, HDPE, Pebax®, Nylon, Urethane, TPE, Multi-layers, Polyimide, Polyimide with Particle Composites, Polyamide-imide, Polyester, Polyphenylsulfone, and others |

| Outer Jacket Materials | All medical-grade polymers, including Nylon, Pebax® and Urethane, Polyimide, Polyimide w/Particle Composites, Polyamide-imide, Polyester, Polyphenylsulfone |

| Reinforcement Materials | 0.0005" x 0.0025" – 0.001" x 0.007" (0.013 x 0.064 mm – 0.025 x 0.178 mm) |

| Typical Flat Wire Size Range | 0.0005" x 0.0025" – 0.001" x 0.007" (0.013 x 0.064 mm – 0.025 x 0.178 mm) |

| Typical Round Wire Size Range | 0.001" – 0.007" (0.025 mm – 0.178 mm) |

| Variable-Pitch Braiders | 16, 32, and 48 carriers |

| Additional Features | Multi-lumen, variable-stiffness continuous processing, multi-durometer, radiopaque fillers, variable-pitch, braid-over-braid, braid-over-coil |

Medical Tubing Capabilities

| · Assembly | · Flaring | · Printing |

| · Bonding | · Forming | · Punching |

| · Braiding or Braid Wire | · Insert Molding | · Shaping |

| · Reinforcement | · Laminating | · Skiving |

| · Coating | · Laser Drilling | · Stretching |

| · Coiling or Coil Wire | · Multi Durometer | · Swaging |

| · Reinforcement | · Multi Segment | |

| · Cutting | · Overmolding |

Typical Materials

| · Aesno (Nylon 12) | · Pebax® (PEBA) | · Polytetrafluoroethylene (PTFE) |

| · (including finished catheter and | · Polyetheretherketone (PEEK) | · Polyurethane TP* (PU TP) |

| · balloon catheter manufacturing) | · Pellethane® (Polyurethane) | · Tecoflex® (Polyurethane) |

| · Besno (Nylon 11) | · Polyester Terephthalate (PET) | · Texin® (TPE) |

| · Braid - Aramid Fibers | · Polyamide (Ny 6 or Ny66) (PA6, PA66, N6, N66) | · Thermoplastic Elastomer (TPE)* |

| · Braid - Round or SS Flat Wire | · Polycarbonate (PC) | · Vestamid® (Nylon 12) |

| · Ethylene Vinyl Acetate (EVA) | · Polyimide (PI) | |

| · Fluoropolymer | · Polyolefin (TPO) | |

| · Fluoropolymer Composite (PTFE-Composite) | · Polyphenylsulfone (PPSU) | |

| · Grilamid® (Nylon 12) | · Polypropylene (PP) | |

| · Nanofiber Composite | · Polyurethane (PU) |

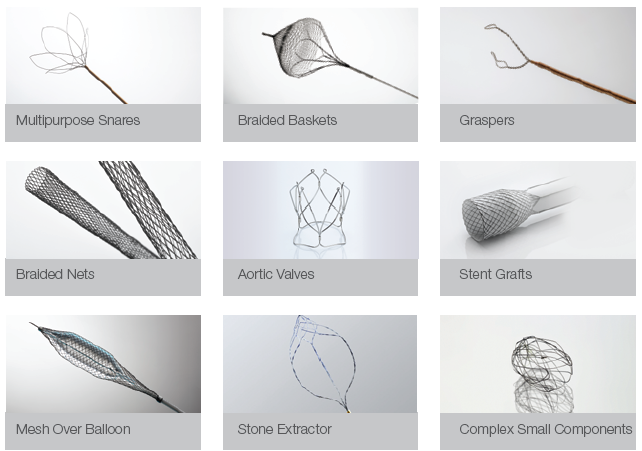

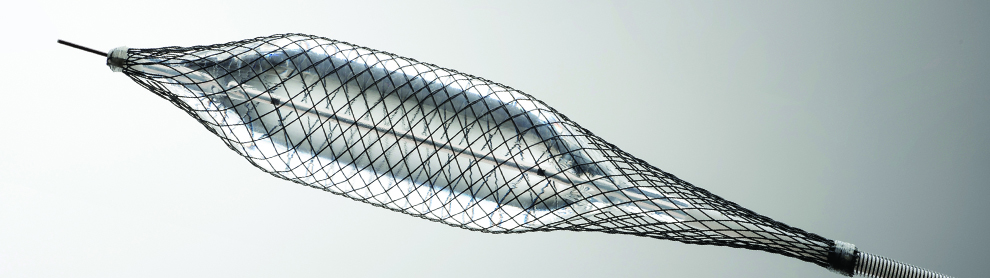

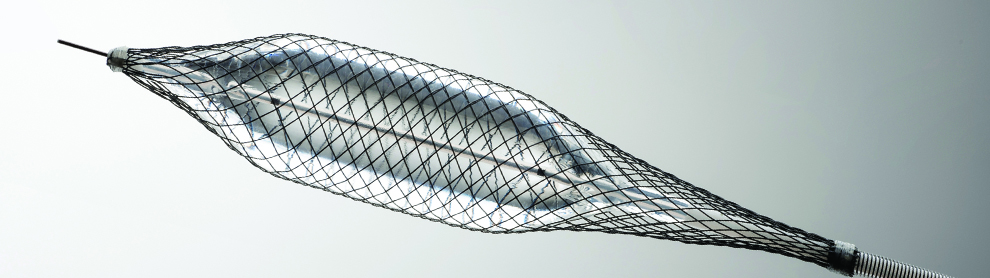

Nitinol Components

Manual forming allows for a more customized product, with a wider range of sizes, shapes, and densities than machine or laser cutting and forming, including:

· Complex geometric structures

· Multilateral closed ends

· Density variations within one product

· Attachment options such as spiral, wavy, or straight tips

· Symmetric and asymmetric structures

Nitinol components are used in minimally invasive devices for markets including urology, neurology, vascular, gastrointestinal, and structural heart. Examples of nitinol-based devices include:

· Multipurpose Snares

· Braided Baskets

· Graspers

· Braided Nets

· Aortic Valves

· Stent Grafts

· Mesh Over Balloon

· Stone Extractor

· Complex Small Components