Precision Miniature and Micro-Sized Metalformed Medical Components and Subassemblies.

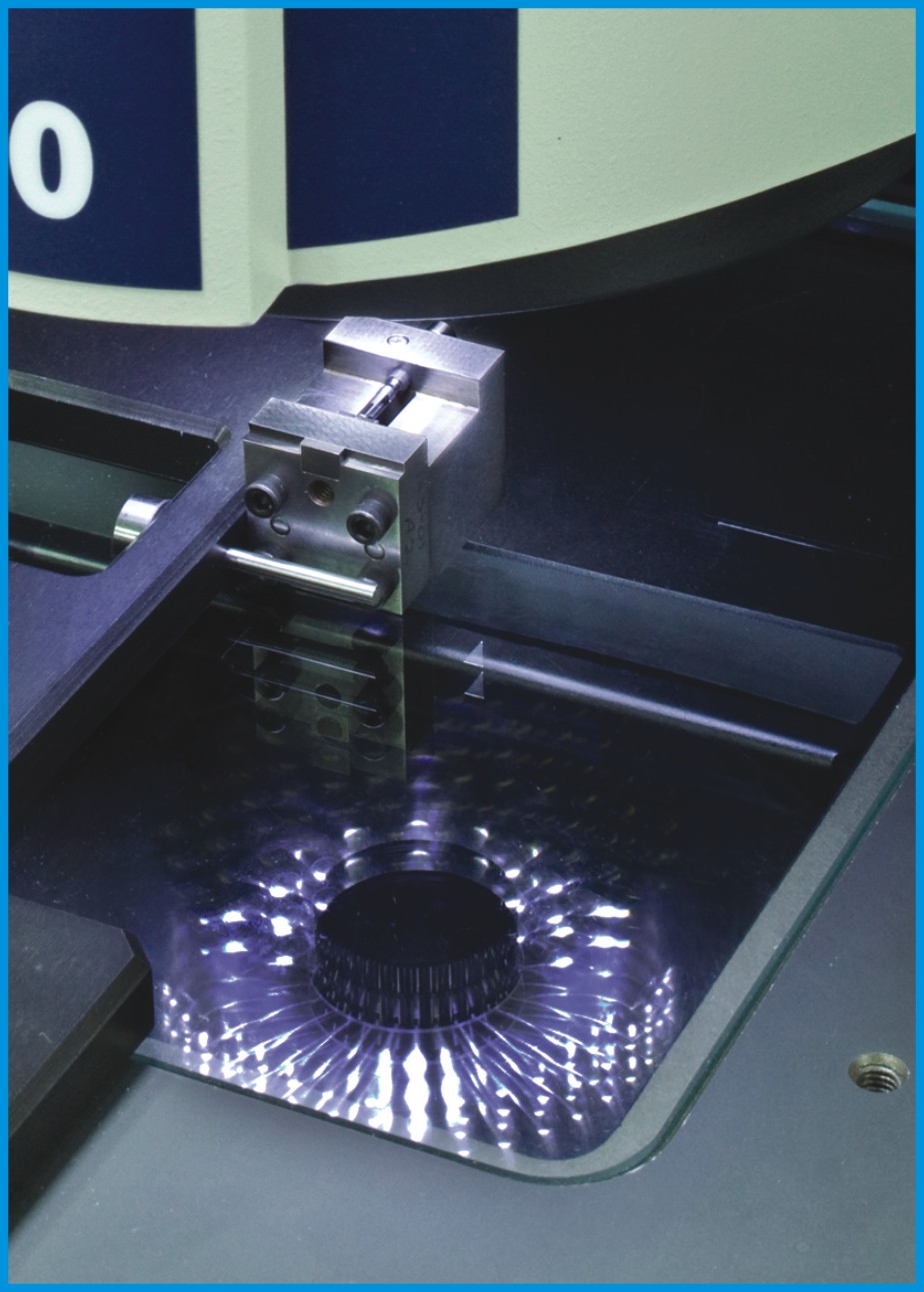

Micro Stamping

Precision Miniature and Micro-Sized

Metalformed Medical Components and Subassemblies

Product Design Assistance for Cost-Saving Conversions from Machining and Metal Injection Molding

· Lower cost, enhanced performance

· Higher strength and performance

· Lot-to-lot dimensional consistency

· High throughput

· Minimally invasive

· Long term reliability

· More complexity in smaller space

· Wall sections down to 0.05mm (.002")

· Tooling to last the life of your program

*Magnified from 5x to more than 80x depending on parts

Technology, Talent, and Experience for Endoscopic, Laparoscopic, Neuromodulation Devices, and More

Implantable Devices and Components

· Anchor tabs

· Bone braces

· Defibrillator components

· Pacemaker components

· Electrodes

· Lamitrodes

· Lead wires

· Marker bands

· Micro-contacts

· Orientation markers

· Radiopaque markers

· Stent markers

· Antennae

Disposable Devices and Components

· Alligator jaws

· Battery tabs

· Biopsy forceps cups

· Biopsy needles

· Bisector blades

· Blade assemblies

· Cardiac

· Clevis

· Distal end

· Endoscopy

· Expandable extenders

· Forceps electrodes

· Laparoscopy

· Restraint bands

· Ring electrode assemblies

· Surgical scissors blades

· Transmitter contacts

Hearing Device Components

· Artificial cochlear

· Digital hearing aid

· Gold plated contacts

· Lead frames

· Micro-contacts

· Variable resistor

Conversion Case Studies

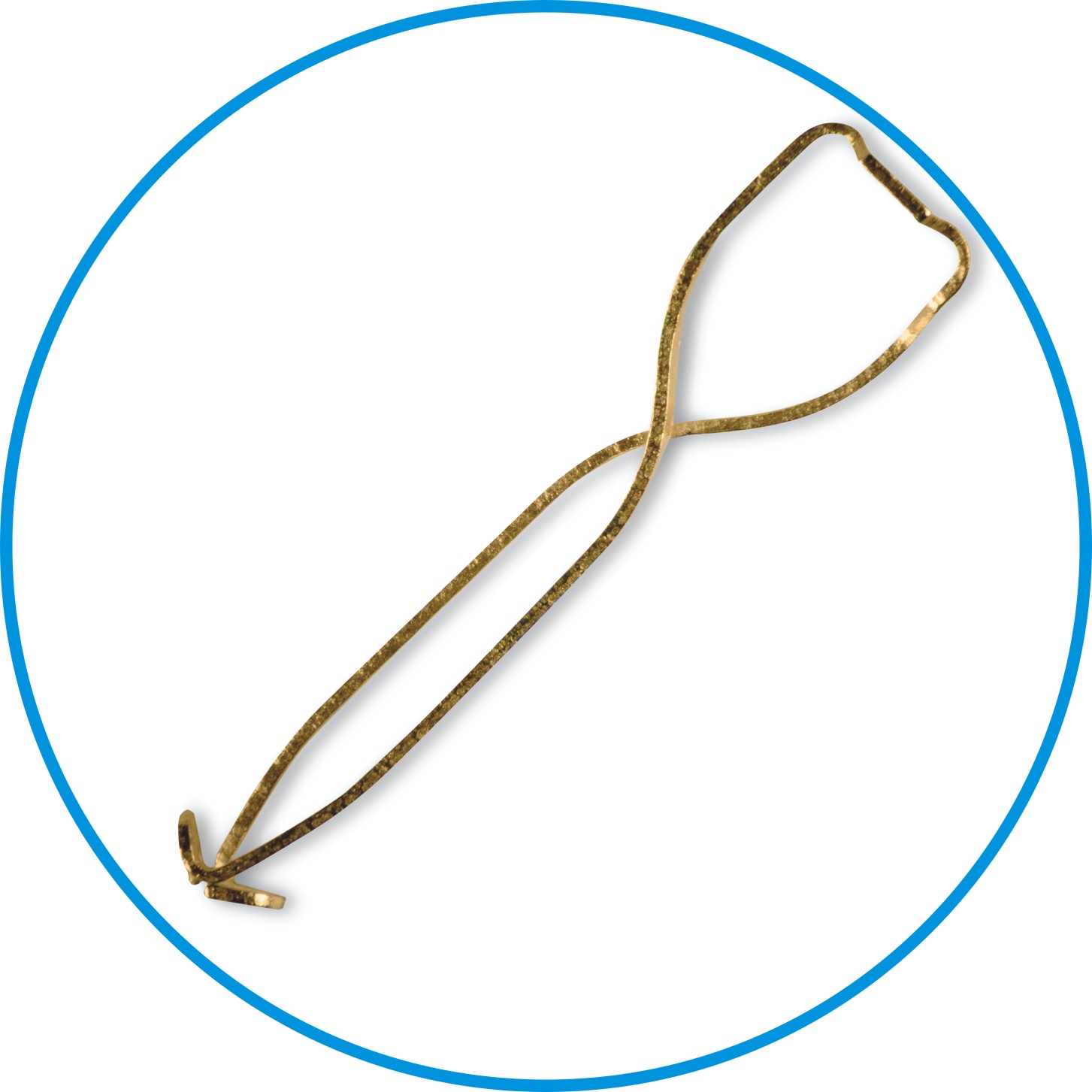

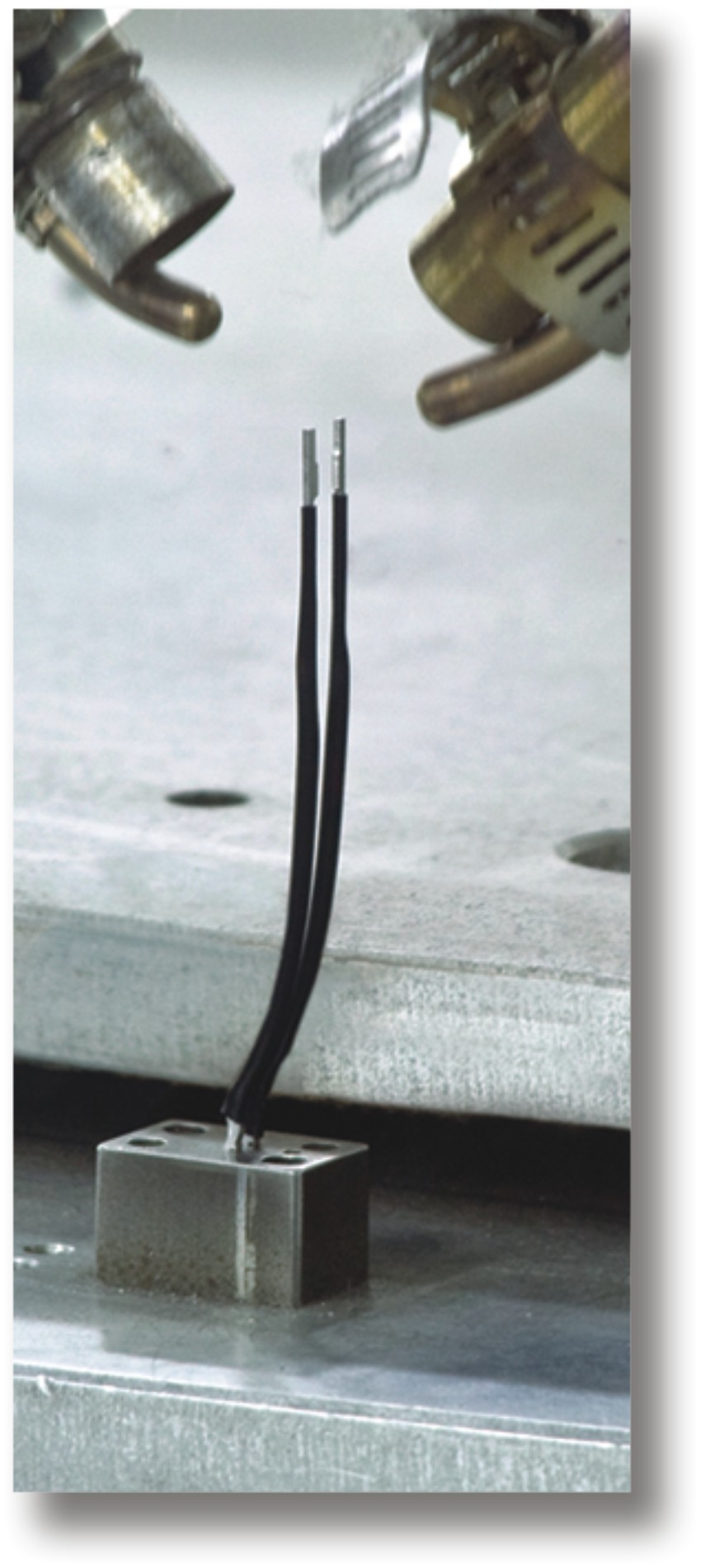

Grasping Forceps

Stainless steel surgical forceps for grasping tissue

Conversion from a taper-grinding and wire bending operation to a labor and cost saving Meier process:

· Sequence of stamping hits for precise control of critical dimensions;

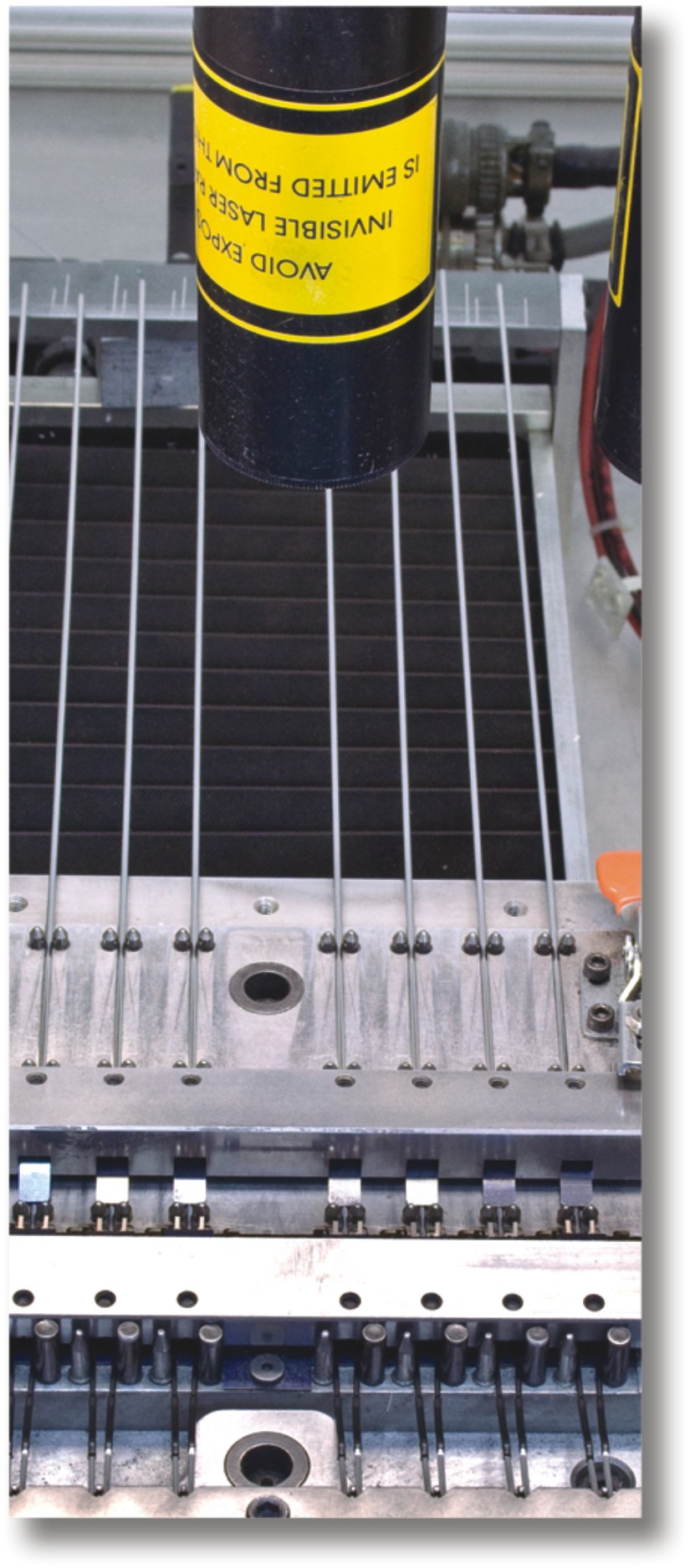

· Integrated SPC process with laser welding and robotic assembly;

· Stainless steel surgical forceps for grasping tissue

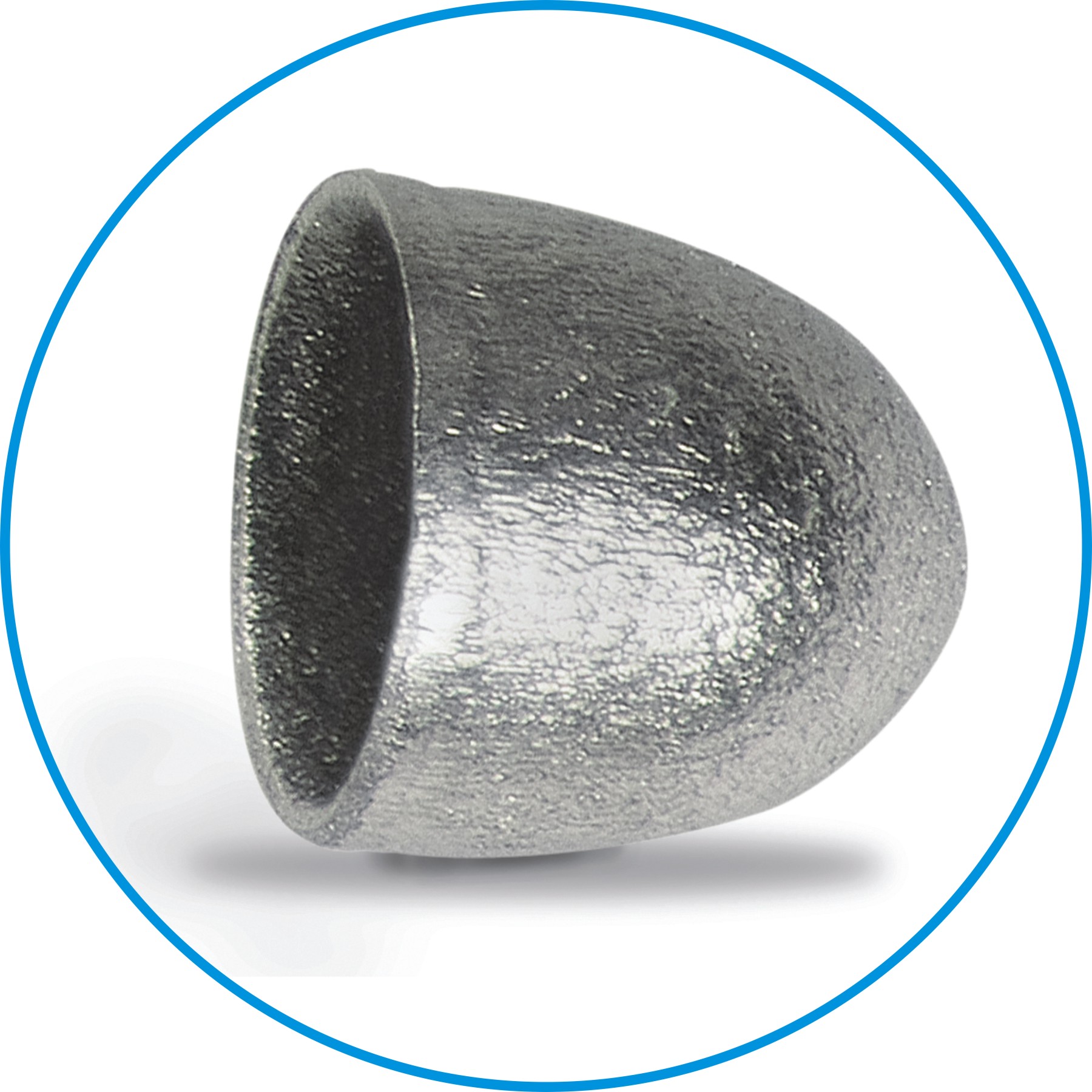

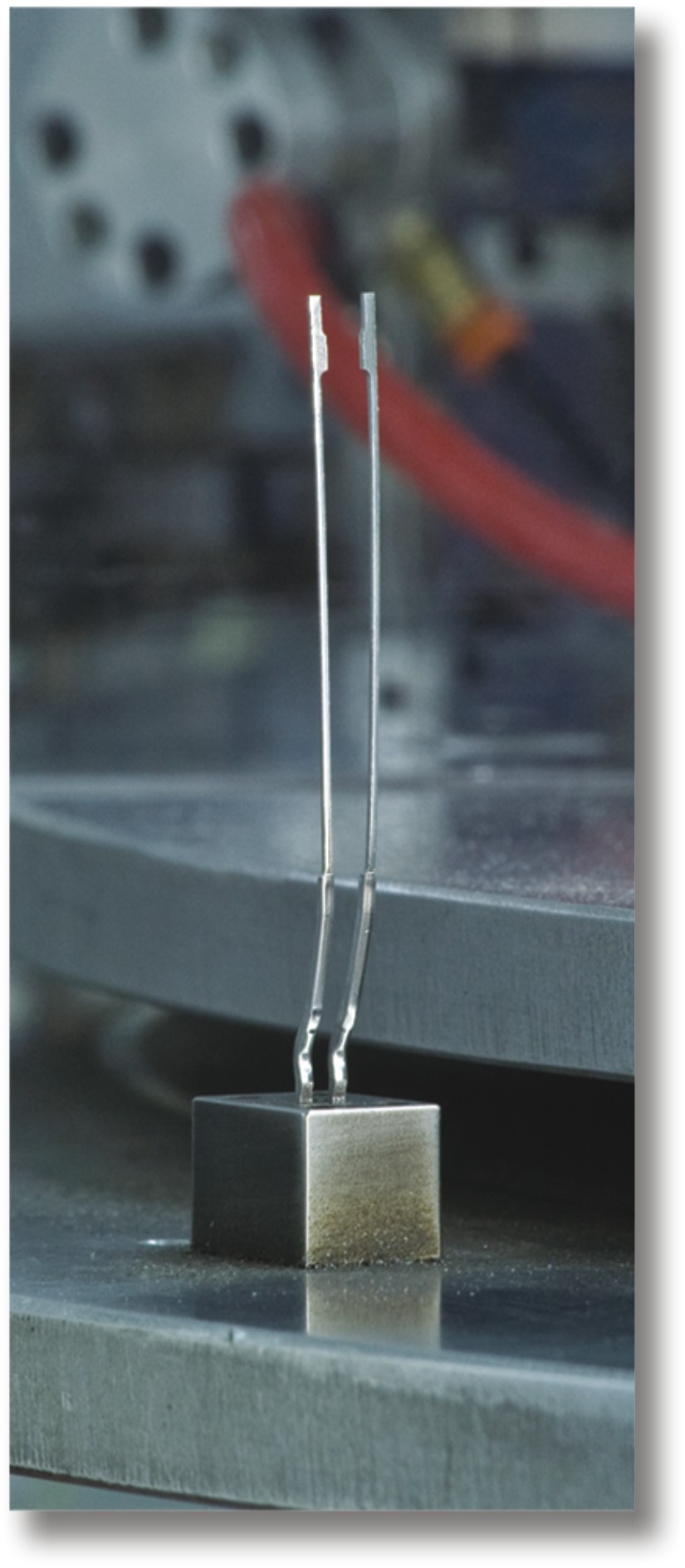

Biopsy Jaw

Disposable stainless steel biopsy jaws less than 3mm wide assembled

Conversion from metal injection molding (MIM) to precision metal forming:

· More precise and consistent geometry for more reliable proper blade mating and function;

· Elimination of pre-assembly sorting and fitting, saving customer time and labor;

· Reduced component costs.

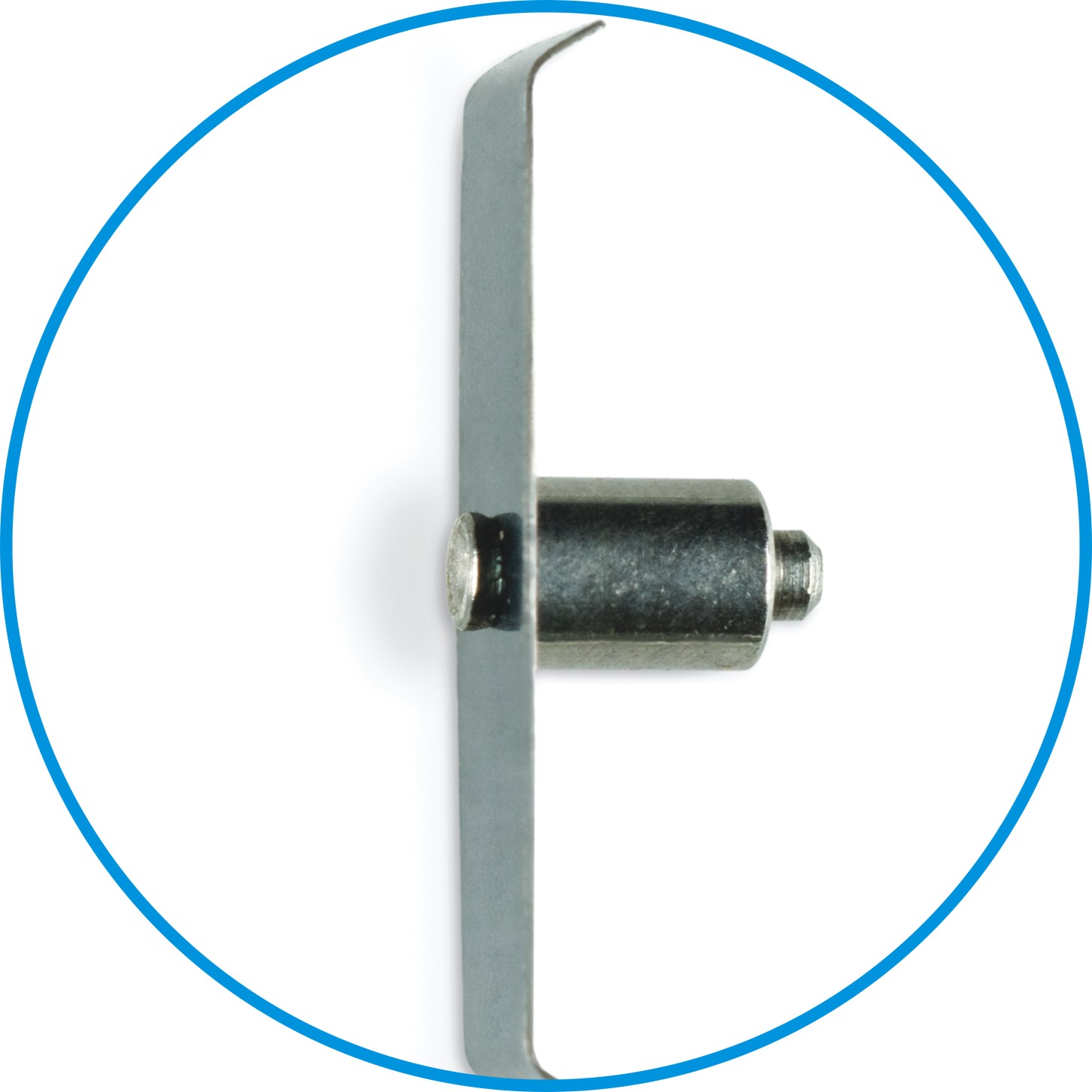

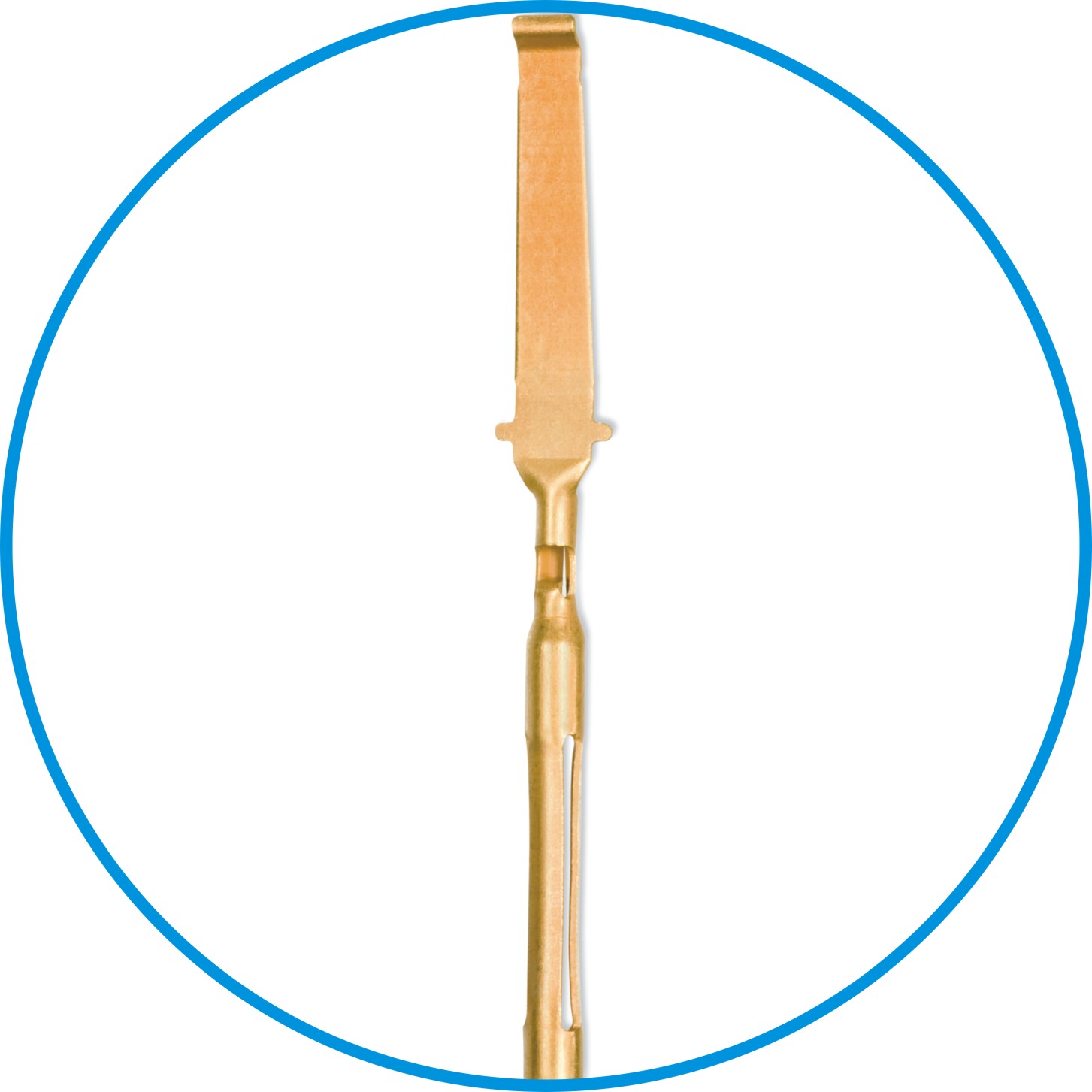

Twisted Biopsy Needle

Miniature needle with tight tolerance hole and specific distal and proximal end angles

Conversion from chemical etching with secondary twisting to single automated stamping and forming process:

· Improved dimensional control for improved performance;

· Streamlined process for customer savings of 60%.

· Reduced component costs.

Alloy

· NiTiNOL

· 300 & 400 Series Stainless Steel

· MP35N

· Beryllium Copper

· Phosphorus Bronze

· Brass

· Aluminum

· PH Grade Stainless Steel

· Nickel 200

· Titanium

· Magnesium

· Hastelloy

· Tantalum

· Permanickel

· Kovar

Precious metals

· Platinum

· Gold

· Silver

· Iridium

· Nickel

Engineered metals

· Precious metals selectively plated only in functional areas to reduce cost

· Thin strips of precious metal bonded to the raw material for enhanced surface integrity

· Multi-gauge strips skived prior to stamping for varying wall thickness

· Continuous strips of hardened materials annealed in specific areas for localized ductility