· Model 105P is designed for discrete length high production winding

· Model 105L is designed for discrete length laboratory or low volume production winding

· Model 130 is designed for continuous length high production winding

· Model 105B is designed for discrete length laboratory or development winding

Builds four different types of Medical Coil Winders

· Model 105P is designed for discrete length high production winding

· Model 105L is designed for discrete length laboratory or low volume production winding

· Model 130 is designed for continuous length high production winding

· Model 105B is designed for discrete length laboratory or development winding

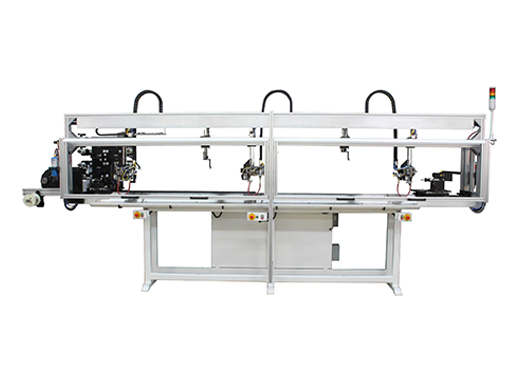

Model 105P Production Medical Coil Winder - Fully Automati Version

The new specially designed series of machines are capable of "mandrel" winding catheters, guidewires and other precision medical coils. Typical coils have .001-.025 inch (.025-.630mm) diameter medical grade stainless steel wire wound over an .001-.188 inch (.025-4.75mm) diameter mandrel. The machines rotate a long mandrel wire between two synchronized spindles while a special nozzle guides the wire. A programmable closed loop tensioner is used to precisely control winding tension. Pitch is calculated to .000001 inch (.0001mm) accuracy and can be changed in .01 revolution of the mandrel. The machine is available in 72, 84, 96, 108, 120 inch (1200, 1500, 1800, 2100, 2400mm) manual or fully automatic versions.

See also the bench top version Model 105B it is available in 12, 24, 36, 48 inch (300, 600, 900, 1200mm) versions.

See also the lighter duty version Model 105L it is available in 48 72, 84, 96, 108, 120 inch (1200, 1500, 1800, 2100, 2400mm) manual or fully automatic versions.

Feature

· MCS4 Control with multi-media

· Auto load of precut or spooled mandrel

· Traverse length 48” to 144” (1200 to 3657mm)

· Mandrel diameter - .001” to .250” (.025 to 6.35mm)

· Wrap filament/wire - .001” to .025” (.025 to .635mm)

· Accurate pitch calculation to .000001” (.0001mm)

· Easily perform multiple pitch changes

· Open, closed or variable pitch

· Round or flat wrap wire

· Programmable mandrel tension

· Programmable wrap wire tension

· Electronically synchronized spindle and tailstock

· High resolution position feedback

· Options:

o Closed loop servo payoff tensioner

o Fully automatic operation

o Manual and Semi-Auto restart

o Manual or air operated collets

o Single, double or triple spindles

o Non-contact back angle sensing

Model 105L Precision Medical Coil Winder - Laboratory Version

The new Model 105L is built on a lighter & smaller frame to easily move into tight quarters in a lab or low production area. The machine retains all of the control performance of the heavier Model 105P machine but limits the amount of fully automatic production features. This new machine has high speed spindles up to 10,000 RPM. A brushless linear servomotor is used to silently drive the traverse. Non-contact lead-lag wire sensing is used to control stiffness in coils. Coated wire is easily wound without damage while maintaining stiffness.

This model has been added to our line of specially designed machines capable of "mandrel" winding catheters, guidewires and other precision medical coils. Typical coils have .001-.025 inch (.025-.630mm) diameter medical grade stainless steel wire wound over an .001-.188 inch (.025-4.75mm) diameter mandrel. The machines rotate a long mandrel wire between two synchronized spindles while a special nozzle guides the wire. A programmable closed loop tensioner is used to precisely control winding tension. Pitch is calculated to .000001 inch (.0001mm) accuracy and can be changed in .01 revolution of the mandrel. The machine is available from 24 to 144 inch (609 to 3657mm) in manual or fully automatic versions.

See also the short version Model 105 it is available in 12, 24, 36 inch (300, 600, 900mm) versions.

Feature

· MCS4 Control with multi-media

· Traverse length 12” to 144” (300 to 3657mm)

· Mandrel diameter - .001” to .250” (.025 to 6.35mm)

· Wrap filament/wire - .001” to .025” (.025 to .635mm)

· Accurate pitch calculation to .000001” (.0001mm)

· Easily perform multiple pitch changes

· Open, closed or variable pitch

· Round or flat wrap wire

· Programmable mandrel tension

· Electronically synchronized spindle and tailstock

· High resolution position feedback

· Single spindle only

· Options:

o Closed loop servo payoff tensioner

o Fully automatic operation

o Manual and Semi-Auto restart

o Manual or air operated collets

o Single-filar, Multi-filar

o Non-contact back angle sensing

Model 130 Continuous Winder

The model 130 is a fully programmable continuous winder, commonly used to wind resistors, heating elements, microcoils and catheters for medical applications. The system shown above includes the Model 130 Continuous Winder, MCS6 Control, a large spool payoff and large spool take up with traverse. The system also includes a cut-to-length feature and adhesive applicator. The machine is capable of continuously winding an over wrap material onto a core material. Accurate tension control is available to control the tension of both the core material as well as the over wrap material. The machine and control are sophisticated enough to change the winding pitch any number of times to any pitch value.

Features

· Fully automatic - winds to length or until material runs out

· Core: .001 to .250" (6.35mm)

· Overwrap: 50 to 20 AWG (.025 to .25mm)

· Programmable tension on core and overwrap material

· Pitch drive: Servomotor driven to 300 in/min

· Accurate pitch calculation to .000001" (.0001mm)

· Product length readout

· Easily do multiple pitch changes

· Options:

o Wound product may be spooled or cut to length

o MCS2 or MCS6 control

o Heat the wound product to stress relieve it

o Apply adhesive and cure it with UV or accelerator

o Cut off wound product to predetermined lengths

o Wind overwrap as Single-filar, Bi-filar, Tri-filar, or Quad-filar

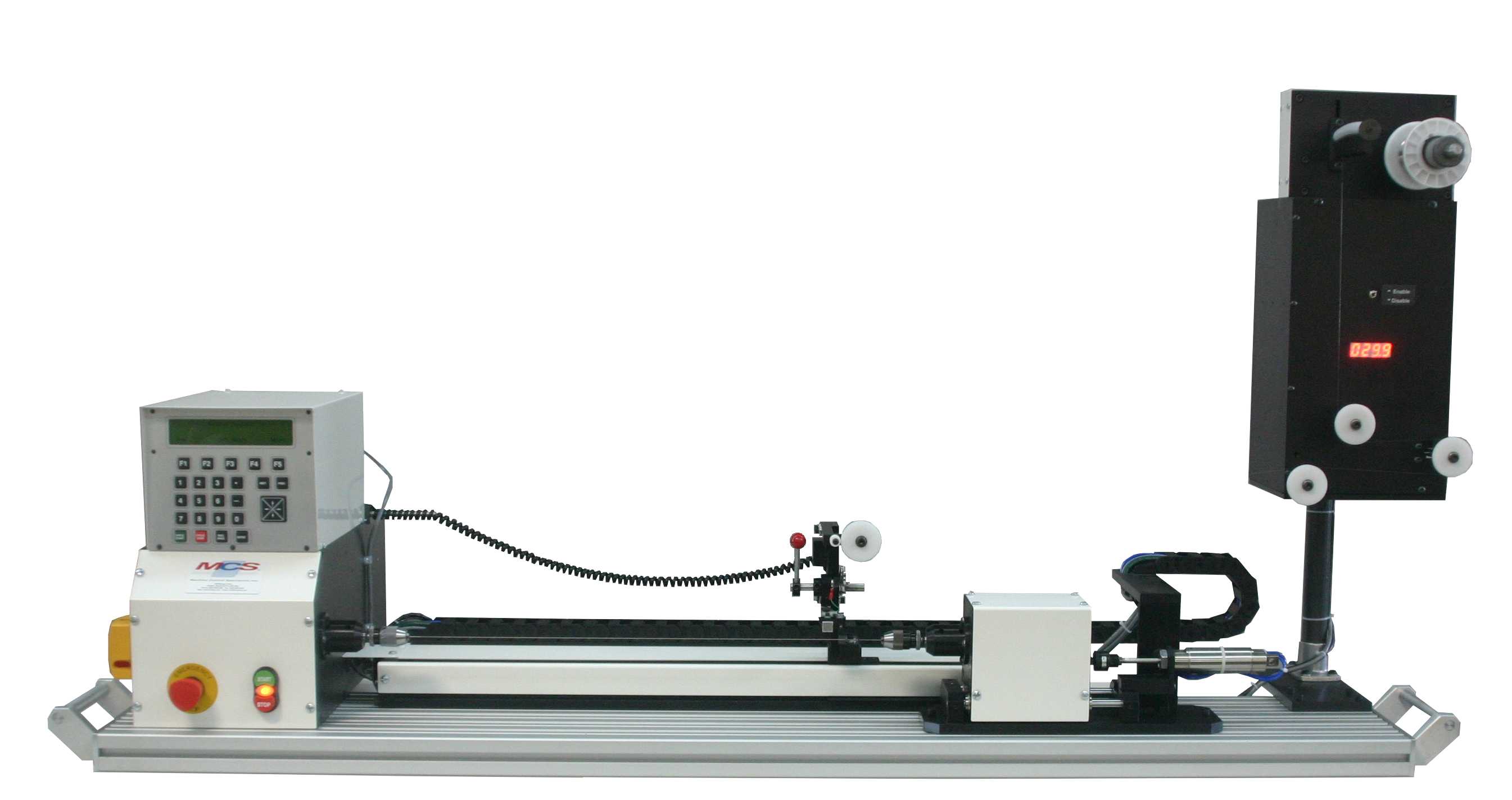

Model 105B Benchtop Precision Medical Coil Winder

The Model 105B is designed to be a laboratory development machine or for low production. It is available in short lengths with the MCS2 or MCS6 control. It does have some semi-automatic features available. The machine above is shown with our Model 1100 closed loop payoff tensioner, that is integrated with the MCS2 control. The Model 105B is available in 12 inch increments up to 72 inches of travel.

See also the long version Model 105L, it is available in 48, 60, 72, 84, 96, 108, 120 inch (1200, 1500, 1800, 2100, 2400mm) in manual, semi-auto, or fully automatic versions.

Feature

· MCS1 Embedded Control

· Traverse length – 12” to 48” (300 to 1200mm)

· Traverse length – 12” to 48” (300 to 1200mm)

· Mandrel diameter - .001” to .250” (.025 to 6.35mm)

· Wrap filament/wire - .001” to .025” (.025 to .635mm)

· Accurate pitch calculation to .000001” (.0001mm)

· Easily perform multiple pitch changes

· Open, closed or variable pitch

· Round or flat wrap wire

· Programmable mandrel tension

· Electronically synchronized spindle and tailstock

· Single-filar or multi-filar

· Manual collets

· Options:

o Closed loop servo payoff tensioner

o Foot pedal control of spindle rotation

o MCS4 Control with multi-media

o Non-contact back angle sensing

Additional Options

· Additional I/O for customer options

· Adhesive application and UV cure

· Barcode scanner for data entry

· Closed loop servo payoff tensioner

· High speed spindle to 10,000 RPM

· In-line hot air stress relieving / NiTi annealing

· Laser ablation

· Leveling casters

· Light tower status indicator

· Programmable air operated mandrel supports

· Vision systems with optional measurement software

· Wire straightener

For a timely response, go to Online enquiry or contact us at info@hngmedical.com .