LaserLinc is a leading supplier of non-contact in-process measurement and process control solutions, including laser and ultrasonic-based technology.

· Laser Micrometers

· Ultrasonic Wall Measurement

· Profile Measurement

· Process Visualization

· Automated Sample Inspection

Laser Micrometers & Ultrasonic Wall Measurement

LaserLinc's gauging and interface products reduce material usage, increase production efficiency, reduce scrap, improve your process and product quality, and document product quality.

Our laser micrometers and ultrasonic wall measurement products are designed by LaserLinc employees at our Fairborn, Ohio office and made in the U.S.A. They are tested and certified to European and North American safety standards including CE, UL, and CSA.

Products

· Laser Micrometers

· Ultrasonic Wall Measurement

· Profile Measurement

· Process Visualization

· Automated Sample Inspection

For a timely response, go to Online enquiry or contact us at +1 905 770 5108 or info@hngmedical.com.

Laser Micrometers

LaserLinc offers 16 different models of laser micrometers for precise, non-contact measurement of outside diameter, ovality, and eccentricity. These measurement tools are used in a variety of continuously extruded plastic and rubber applications such as insulated wire, cable, hose, pipe, monofilament, and medical tubing. Additional examples include optical fiber, glass rod and tube, synthetic cork for wine bottles, drawn wire, tube, bar, and other metal profiles.

· Triton™ Triple-Axis Micrometers

Ultrasonic Wall Measurement

LaserLinc offers ultrasonic devices for measuring wall thickness or layer thickness of plastic, rubber, glass, and metal products like tubing, hose, pipe, insulated wire, and cable.

· Ultrasonic Sensor Assemblies

Profile Measurement

Our Profile Vu™ system is a high-speed non-contact measurement and defect detection system that continuously monitors critical features in rubber, plastic, wood, shaped metals, wire, cable, and more. The system’s 360-degree surface coverage means superior defect detection capabilities when compared to laser micrometers. Defects can be detected in-process and reviewed in 3D.

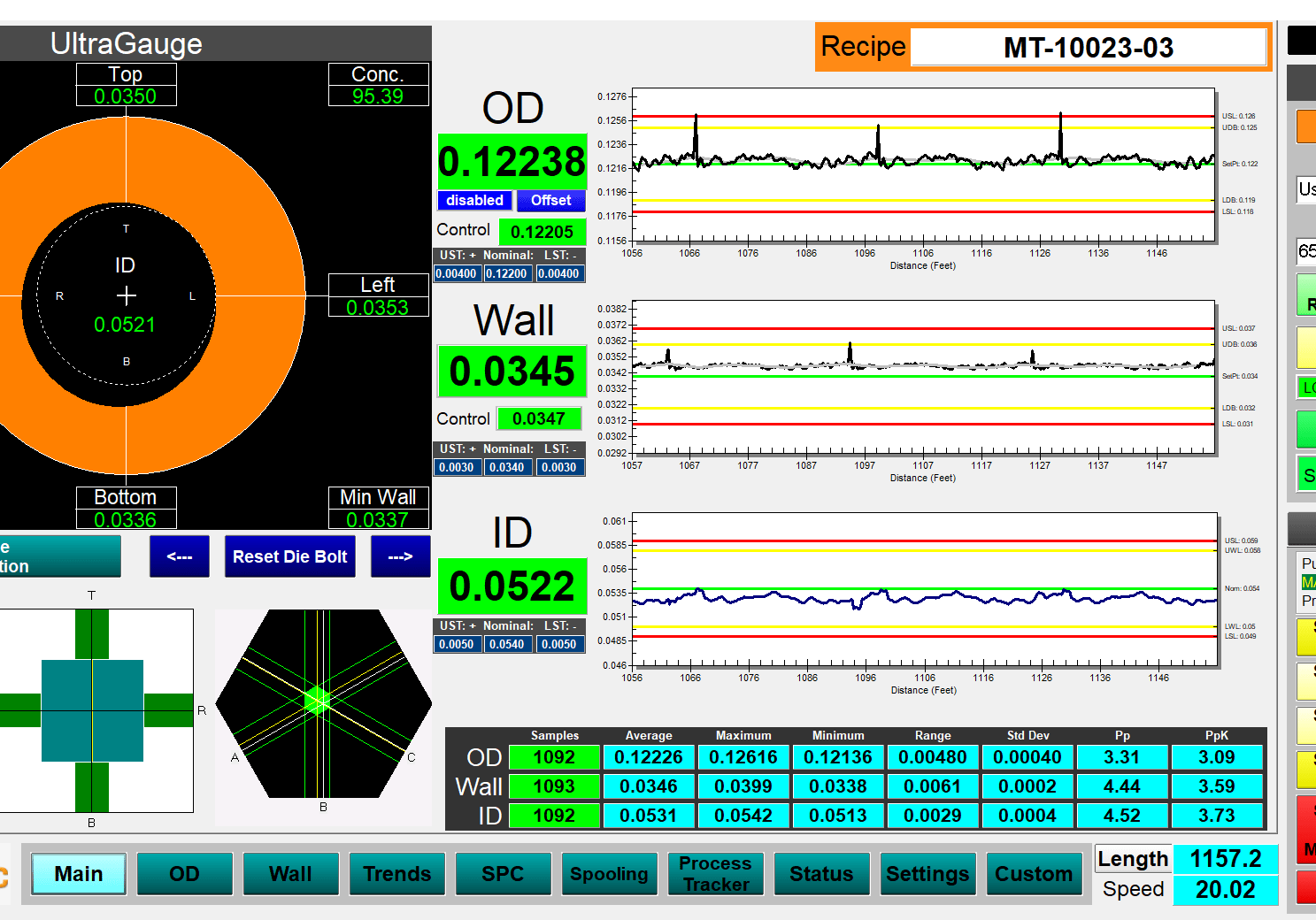

Process Visualization

Gauges provide huge amounts of instantaneous data in real-time, so it’s impossible for an operator to assimilate what is happening in the process. That’s why LaserLinc developed a unique open-architecture software solution for process visualization allowing its own instruments and those of other vendors to be connected via a variety of gauge interfaces for process monitoring, display, control, and reporting.

- Off-the-shelf Total Vu software allows all stakeholders to get exactly what they need from an adaptable production monitoring and control system. Operators have access to data to help them operate the line more efficiently. Engineers have monitoring, control and reporting tools to document and improve processes. Managers gain peace of mind that engineers and operators have the tools they need to reduce costs, increase production, and improve quality.

- The SmartLinc™ processor is a robust and reliable platform for delivering fast, accurate measurements of product diameter, ovality, and other values directly to your line control system using standard industrial protocols such as EtherNet/IP. Integration with your PLC, HMI/MMI, or other EtherNet/IP-enabled devices is quick and easy. SmartLinc display provides a rugged 7-inch color touchscreen solution for bench or on-line locations.

Automated Sample Inspection

LaserLinc’s non-contact solutions are well suited to off-line sample measurement. Our products ensure accuracy and simplify the quality inspectors job. You can virtually eliminate operator error through non-contact measurement and automatic checking and recording of results. Choose from a variety of part-holding or guiding fixtures to suit your specific needs. All our sample measurement products work seamlessly with our Total VuTM open-architecture platform.

· TrDiameter, Length, Taper (Metron)