· Interventional Radiology

· Diabetes Management

· Peripheral Vascular

· Gastroenterology

· Ear/Nose/Throat

· Cardiovascular

· Orthopedics/Spine

· Endoscopy/Laparoscopy

· Neurology

· Oncology

· Urology

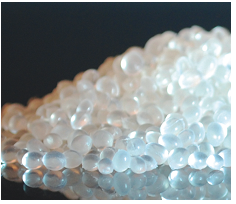

Our polyether-based polymers have less in-vivo softening than other industry-recognized ether-based materials. With a long history of reliable performance in short term implantable devices they have the versatility to be used across a broad range of applicational areas including catheters, ports and access devices. These materials are listed under the trade names: ChronoThane P, ChronoThane T

ChronoThane®T (CT T)

Versatile and effective, Strong dimensional control through ease of manufacturability

Aliphatic Polyether-Based Urethanes

Description

· ChronoThane T is a family of aliphatic ether based polyurethane elastomers.

· These biocompatible materials possess characteristics such as low coefficient of friction, low extractables, dimensional stability, high impact resistance, and excellent tear strength.

· ChronoThane T can be tailored to meet specific Melt Flow Index ranges to suit your manufacturing or extrusion processes.

· These materials are available in hardnesses ranging from 75 Shore A to 75 Shore D.

· Pre-Processing Recommendations:

· ChronoThane T processing can be optimized by drying to a moisture content equal to or less than 0.05% by weight prior to melt processing.

Features & Benefits

· DIMENSIONAL STABILITY

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· EASE OF PROCESSING

· HIGH IMPACT RESISTANCE

· LOW COEFFICIENT OF FRICTION

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· CONSISTENT ELASTOMERIC PERFORMANCE

· AVAILABLE IN SOLUTION FORM

· NON CYTOTOXIC

· LOW EXTRACTABLES

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

CHRONOTHANE T (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 75 Shore A – 75 Shore D | |

Water Absorption | 1.00 – 1.16% | D570 |

Melt Flow | 2-26 g/10 min । 170-205° C/2.16 kg-3.26 kg | D1238 |

Durometer | 80A | 93A | 93A-B20 | 93A-B40 | |

Ultimate Tensile Strength (psi) | 4900-6200 | 3000-8000 | 5400-7000 | 4000-6500 | D638 |

Tensile (psi) | |||||

@ 50% elongation | 300-550 | 650-900 | 900-1100 | 1100-1400 | D638 |

@ 100% elongation | 550-800 | 1000-2000 | 1000-1600 | 1400-1800 | D638 |

@ 200% elongation | 900-1400 | 1700-2500 | 1800-2300 | 2000-2300 | D638 |

@ 300% elongation | 1300-2100 | 2600-4300 | 2800-3100 | 2700-3100 | D638 |

Ultimate Elongation (%) | 550-800 | 350-650 | 400-650 | 400-600 | D638 |

*Data provided herein is meant to show a general range for the ChronoThane T product lines; these properties can be tailored to meet specific values based on customer requirements.

ChronoThane®P (CT P)

ROBUST, RESILIENT AND ADAPTABLE: HIGH PERFORMANCE WITH SUPERIOR ADAPTABILITY

Aromatic Polyether-Based Urethanes

Description

· ChronoThane P is a family of aromatic ether based polyurethane elastomers. With a long history of reliable performance, this medical grade polymer has the versatility to be used across a broad range of applicational areas including catheters, ports and access devices.

· These biocompatible materials possess characteristics such as low coefficient of friction, low extractables, dimensional stability, high impact resistance, and excellent tear strength.

· ChronoThane P allows for ease of manufacturability and can be processed using conventional extrusion or injection molding equipment. These materials are available in hardnesses ranging from 75 Shore A to 75 Shore D.

Features & Benefits

· DIMENSIONAL STABILITY

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· EXCELLENT TEAR STRENGTH

· HIGH IMPACT RESISTANCE

· LOW COEFFICIENT OF FRICTION

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· CONSISTENT ELASTOMERIC PERFORMANCE

· AVAILABLE IN SOLUTION FORM

· NON CYTOTOXIC

· LOW EXTRACTABLES

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

CHRONOTHANE P (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 75 Shore A – 75 Shore D | |

Water Absorption | 1.17 – 1.37% | D570 |

Melt Flow | 2-26 g/10 min । 190°-205º C/3.26 kg | D1238 |

Mechanical Property Ranges (typical example ranges shown)*

Durometer | 80A | 55D | |

Ultimate Tensile Strength (psi) | 4000 – 7000 | 5000-8000 | D638 |

Tensile (psi) | |||

@ 50% elongation | 650 – 850 | 3000-3500 | D638 |

@ 100% elongation | 800 – 1000 | 3400-3800 | D638 |

@200% elongation | 1200 – 1400 | 4000-4700 | D638 |

@ 300% elongation | 1650 – 2000 | 5000-5600 | D638 |

Ultimate Elongation (%) | 680 – 850 | 300-500 | D638 |

*Data provided herein is meant to show a general range for the ChronoThane P product lines; these properties can be tailored to meet specific values based on customer requirements.

ChronoFlex® (CF)

· Polycarbonate-based materials

· Good biocompatibility, excellent solvent resistance and long-term permanent durability

· Minimize surface degradation and resistance to environmental stress cracking (ESC)

ChronoFlex®AL (CF AL)

EXCEPTIONALLY STRONG, SAFE AND DEPENDABLE

Aliphatic Polycarbonate-Based Urethanes

Description

· ChronoFlex AL is a family of biodurable aliphatic polycarbonate-based thermoplastic urethanes designed to overcome surface degradation such as stress-induced microfissures.

· With a long history of reliable performance in both long and short term devices, this medical grade polymer has the versatility to be used across a broad range of applicational areas ranging from oncology and neurology to cardiovascular disease management.

· These ether-free polyurethane elastomers are biostable and display a low modulus of elasticity, excellent solvent resistance and limited softening in-vivo.

· These products are adaptable to most standard manufacturing processes and are available in hardnesses ranging from 75 Shore A to 75 Shore D.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· LIMITED IN-VIVO SOFTENING

· EXCELLENT CHEMICAL RESISTANCE

· INHERENT MATERIAL STRENGTH

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· RELIABLE PERFORMANCE IN LONG AND SHORT TERM IMPLANTABLE DEVICES

· AVAILABLE IN SOLUTION FORM

· ESC RESISTANT

· LOW MODULUS OF ELASTICITY

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

ChronoFlex AL (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 75 Shore A – 75 Shore D | |

Specific Gravity | 1.10 – 1.40 | D792 |

Melt Flow | 2 – 26 g/10 min | 205° C/3.26 kg | D1238 |

Durometer | 75A-B20* | 55D | 75D | ASTM |

Ultimate Tensile Strength (psi) | 4000-9000 | 5000-10000 | 3000-8000 | D638 |

Tensile (psi) | ||||

@ 50% elongation | 350-650 | 1500-1800 | 3000-8000 | D638 |

@ 100% elongation | 550-850 | 1800-2200 | 3000-8000 | D638 |

@200% elongation | 800-1200 | 2800-4200 | - | D638 |

@300% elongation | 1200-2000 | 4200-10000 | - | D630 |

Ultimate Elongation (%) | 350-750 | 200-400 | 100-300 | D638 |

*Data provided herein is meant to show a general range for the ChronoFlex AL product lines; these properties can be tailored to meet specific values based on customer requirements.

STRENGTH YOU CAN RELY ON; RELIABILITY YOU CAN TRUST.

Aromatic Polycarbonate-Based Urethanes

Description

· ChronoFlex AL is a family of biodurable aliphatic polycarbonate-based thermoplastic urethanes designed to overcome surface degradation such as stress-induced microfissures.

· With a long history of reliable performance in both long and short term devices, this medical grade polymer has the versatility to be used across a broad range of applicational areas ranging from oncology and neurology to cardiovascular disease management.

· These ether-free polyurethane elastomers are biostable and display a low modulus of elasticity, excellent solvent resistance and limited softening in-vivo.

· These products are adaptable to most standard manufacturing processes and are available in hardnesses ranging from 75 Shore A to 75 Shore D.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· LIMITED IN-VIVO SOFTENING

· EXCELLENT CHEMICAL RESISTANCE

· INHERENT MATERIAL STRENGTH

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· RELIABLE PERFORMANCE IN LONG AND SHORT TERM IMPLANTABLE DEVICES

· AVAILABLE IN SOLUTION FORM

· ESC RESISTANT

· LOW MODULUS OF ELASTICITY

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

ChronoFlex C (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 75 Shore A – 75 Shore D | |

Water Absorption | 1.00% | D570 |

Melt Flow | 2 – 26 g/10 min | 205° C/3.26 kg | D1238 |

MECHANICAL PROPERTY RANGES

Durometer | 80A | 75D | |

Ultimate Tensile Strength (psi) | 5500-8000 | 4500-6500 | D638 |

Tensile (psi) | |||

@ 50% elongation | 500-700 | 4200-5000 | D638 |

@ 100% elongation | 800-1000 | 4500-5200 | D638 |

@ 200% elongation | 1900-2100 | 4900-5800 | |

@ 300% elongation | 5200-6000 | - | D638 |

Ultimate Elongation (%) | 300-500 | 200-350 | D638 |

*Data provided herein is meant to show a general range for the ChronoFlex C product lines; these properties can be tailored to meet specific values based on customer requirements.

STRENGTH, ELONGATION AND DURABILITY IN LIQUID FORM.

Solution-based polycarbonate urethanes

Description

· The ChronoFlex AR and ChronoFlex AR-LT product lines are polycarbonate urethanes designed for molding, casting and dip coating applications. These unique materials are fully synthesized in liquid providing superior strength & elongation while maintaining the inherent polycarbonate advantage of long-term permanent durability and resistance to Environmental Stress Cracking (ESC). Additionally, they may be electrospun or used in water emulsion processes.

· ChronoFlex AR & AR-LT polymers are ideal in applications requiring exceptional flexural endurance such as artificial heart diaphragms, vascular grafts, or for use in the fabrication of blood contact surfaces, such as coatings.

· The ChronoFlex AR & AR-LT demonstrates an inherent low-tack property, which allows for pulsatile flow in-situ, an innovative characteristic optimal for devices such as VADs and artificial valves components.

· This product line is offered in a wide range of viscosity/concentration configurations based upon specific product requirements.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· LIQUID POLYMER

· SELF SEALING

· SUPERIOR ELASTICITY

· MOLDABLE/CASTABLE

· INHERENT MATERIAL STRENGTH

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· RELIABLE PERFORMANCE IN LONG AND SHORT TERM IMPLANTABLE DEVICES

· LOW THROMBOGENICITY

· ESC RESISTANT

· CAN BE ELECTROSPUN

· DIP COATABLE

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

ChronoFlex AR and AR-LT (typical example ranges shown)*

MECHANICAL PROPERTIES

CF AR | CF AR LT | ASTM Standard | |

% Solids (+/- 2%) | 8% - 25% | 8% - 25% | |

Viscosity (cps) | |||

@ 8% Solids | 100 - 800 | 200 - 1,000 | |

@ 22% Solids | 10,000 - 50,000 | 15,000 - 50,000 | |

Ultimate Tensile Strength (psi) | 3,000 - 10,000 | 6,000 - 10,000 | D638/D882 |

Tensile (psi) | |||

@50% elongation | 250 – 600 | 450 – 850 | D638/D882 |

@100% elongation | 400 – 1000 | 650 – 1200 | D638/D882 |

@200% elongation | 700 – 2000 | 1000 – 2300 | D638/D882 |

@300% elongation | 950 – 3500 | 1600 – 4000 | D638/D882 |

Ultimate Elongation (%) | 600 – 1200 | 500 – 1100 | D638/D882 |

*Data provided herein is meant to show a general range for the ChronoFlex AR and ChronoFlex AR-LT product lines; these properties can be tailored to meet specific values based on customer requirements.

SOFT, COMPLIANT AND ELASTIC, YET DURABLE, RESILIENT AND ROBUST.

Thermoplastic Rubber Elastomers

Description

· This biocompatible elastomer may be considered as a substitute for rubber, latex and silicone materials. Though soft and compliant, the ChronoPrene resins offer a high flexural modulus, as well as a superior combination of tensile strength and elongation.

· An easy molding, high-flow rubber, ChronoPrene can be processed using conventional extrusion, injection molding and blowmolding methods. Its physical properties make it an optimal material for applications requiring rubber or elastic characteristics, such as compliant/ non-compliant balloons, endoscopic and laparoscopic inflation bags.

· ChronoPrene can be processed at low temperatures, resulting in excellent surface smoothness and superior elasticity. ChronoPrene exhibits high abrasion resistance, durability and UV stability and is available in hardnesses ranging from 5 Shore A to 75 Shore A.

Features and benefits

· BIODURABLE

· SUPERIOR ELASTICITY

· AVAILABLE IN RADIOPAQUE FORM

· PHTHALATE FREE

· EXCELLENT CHEMICAL RESISTANCE

· HYDROPHOBIC

· BIOCOMPATIBLE

· OUTSTANDING SUBSTITUTE FOR RUBBER OR LATEX MATERIALS

· EXCEPTIONALLY SOFT

· EXTRUDABLE / INJECTION MOLDABLE

· UV STABLE

· HIGH ELONGATION

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

CHRONOPRENE (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 5 Shore A – 75 Shore A | |

Melt Flow | 2-26 g/10 min । 190º-205° C/ 2.16-8.26 kg | D1238 |

Mechanical Properties

Durometer | 5A | 15A | 40A | 75A | ASTM |

Ultimate Tensile Strength (psi) | 50-100 | 900-1300 | 400-600 | 1200-1400 | D638 |

Tensile (psi) | |||||

@ 50% elongation | 2 - 10 | 20-30 | 70-90 | 825-975 | D638 |

@ 100% elongation | 10 - 20 | 40-50 | 110-130 | 975-1100 | D638 |

@ 200% elongation | 20 - 30 | 60-80 | 160-180 | 1100-1300 | D638 |

@ 300% elongation | 30 - 35 | 80-100 | 210-230 | 1300-1400 | D638 |

Ultimate Elongation (%) | 700-900 | 1700-1950 | 600-900 | 250-350 | D638 |

*Data provided herein is meant to show a general range for the ChronoPrene product lines; these properties can be tailored to meet specific values based on customer requirements.

STRONG YET SUPPLE: THE POWER OF POLYCARBONATE MEETS THE SOFTNESS OF SILICONE.

Thermoplastic Silicone Polycarbonate Elastomers

Description

· ChronoSil is a family of polycarbonate based silicone elastomers. These biocompatible materials maintain the inherent benefits of polycarbonate-based urethanes, including high pressure resistance, tensile-strength and superior chemical resistance combined with silicone’s industry recognized advantages such as heightened elongation, superior elasticity and a low coefficient of friction.

· Consistent with other polycarbonate-based materials, ChronoSil can be synthesized to provide targeted mechanical properties and is resistant to Environmental Stress Cracking (ESC).

· These products are adaptable to most standard manufacturing processes and are available in hardnesses ranging from 75 Shore A to 75 Shore D.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· HIGH PRESSURE RESISTANCE

· HEIGHTENED ELONGATION

· SUPERIOR TENSILE STRENGTH

· INHERENT MATERIAL STRENGTH

· BIOCOMPATIBLE

· AVAILABLE IN ANTIMICROBIAL FORMS

· RELIABLE PERFORMANCE IN LONG AND SHORT TERM IMPLANTABLE DEVICES

· AVAILABLE IN SOLUTION FORM

· ESC RESISTANT

· SUPERIOR ELASTICITY

· LOW COEFFICIENT OF FRICTION

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

CHRONOSIL (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 75 Shore A – 75 Shore D | |

Silicone Content Available | 5% - 20% | |

Water Absorption | 0.59 - 0.62% | D570 |

Melt Flow | 2 – 26 g/10 min | 205° C/3.26 kg | D1238 |

MECHANICAL PROPERTIES*

Durometer | 80A | 55d | |

% Silicone | 5% | 5% | |

Ultimate Tensile Strength (psi) | 3300 - 7000 | 5000-10,000 | D638 |

Tensile (psi) | |||

@ 50% elongation | 350 - 600 | 2000 - 2500 | D638 |

@ 100% elongation | 500 - 800 | 2500 - 3000 | D638 |

@ 200% elongation | 900 - 1250 | 3500 - 4500 | |

@ 300% elongation | 1500 - 2100 | 4600 - 5500 | D638 |

Ultimate Elongation (%) | 450 - 650 | 350 - 550 | D638 |

*Data provided herein is meant to show a general range for the ChronoSil product lines; these properties can be tailored to meet specific values based on customer requirements.

SMOOTH AND PLIABLE; STRETCHING BEYOND THE BOUNDARIES.

Aromatic Thermoplastic Polyurethane Elastomers

Description

· PolyBlend is a family of exceptionally soft, aromatic polyurethane elastomeric alloys, which can be used as a substitute for natural rubber or latex in many applications.

· These polymers encompass unique characteristics such as low flexural modulus, moderate tensile strength, and high elongation, in addition to allowing for a high draw-down ratio due to its superior melt strength and chemical integrity.

· PolyBlend can be processed on conventional extrusion or injection molding equipment and is available in hardnesses ranging from 45 Shore A to 80 Shore A.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· AVAILABLE IN RADIOPAQUE FORM

· ALLOWS FOR HIGH DRAW DOWN RATIOS

· SUPERIOR MELT STRENGTH

· BIOCOMPATIBLE

· EXCELLENT SUBSTITUTE FOR RUBBER OR LATEX MATERIALS

· EXCEPTIONALLY SOFT

· EXTREMELY FLEXIBLE

· EXTRUDABLE / INJECTION MOLDABLE

· HIGH ELONGATION

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

PolyBlend (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 45 Shore A – 80 Shore A | |

Water Absorption | 0.067 – 0.28% | D570 |

Melt Flow | 2-26 g/10 min । 190º-205° C/ 2.16-8.26 kg | D1238 |

Mechanical Properties

Durometer | 45A | 55A | 80A | |

Ultimate Tensile Strength (psi) | 1700 – 2100 | 700-900 | 1100-4250 | D638 |

Tensile (psi) | ||||

@ 50% elongation | 40 – 100 | 100-150 | 450-700 | D638 |

@ 100% elongation | 100 – 150 | 150-200 | 600-850 | D638 |

@ 200% elongation | 150 – 200 | 200-250 | 750-1100 | D638 |

@ 300% elongation | 175 – 250 | 275-300 | 950-1300 | D638 |

Ultimate Elongation (%) | 1350 - 1700 | 950-1100 | 400-950 | D638 |

*Data provided herein is meant to show a general range for the PolyBlend product lines; these properties can be tailored to meet specific values based on customer requirements.

THE LUBRICITY OF A HYDROGEL; THE MECHANICAL STRENGTH TO WITHSTAND EXTRUSION

Hydrophilic Thermoplastic Elastomers

Description

· HydroThane is a hydrophilic thermoplastic polyurethane elastomer, ranging in water absorption rates from 5% to 25%. This unique extrudable hydrophilic product line was designed to provide maximum physical properties for use in extruded or injection molded components, while allowing for consistent single-step surface lubricity characteristics and a low coefficient of friction.

· Available in aliphatic and aromatic versions, these elastomers have the ability to rapidly absorb water while maintaining high tensile strength and high elongation, resulting in a permanently lubricious polymer.

· HydroThane can be processed using conventional extrusion or injection molding equipment.

· Being hydrophilic even when dehydrated, they should be sealed and stored in a cool, dry place and are available in hardnesses of 80 Shore A and 93 Shore A.

Features and benefits

· BIODURABLE

· TAILORED TO MEET MECHANICAL SPECIFICATIONS

· WATER ABSORPTION RATES FROM 5% - 25%

· HIGH TENSILE STRENGTH

· BIOCOMPATIBLE

· TARGETED HYDROPHILICITY

· EXTRUDABLE / INJECTION MOLDABLE

· SUPERIOR ELONGATION

· USP CLASS VI

· ANIMAL-FREE ORIGIN CERTIFIED

Mechanicals

HydroThane AL (typical example ranges shown)* | ASTM Standard | |

Durometer Range Available | 80 Shore A – 93 Shore A | D792 |

Water Content | 5 – 20% (by weight) | D570 |

Melt Flow | 2-26 g/10 min । 190°-205° C/2.16 kg | D1238 |

Mechanical Properties

Hydrated | Non-Hydrated | ASTM | |

Durometer | 93A | 93A | |

Ultimate Tensile Strength (psi) | 2000–3000 | 4800–5500 | D638 |

Tensile (psi) | |||

@ 50% elongation | 600–800 | 800–1050 | D638 |

@ 100% elongation | 900–1200 | 1200-1500 | D638 |

@ 200% elongation | 1300–1700 | 1800-2200 | D638 |

@ 300% elongation | 1500–2100 | 2400-2800 | D638 |

Ultimate Elongation (%) | 450–650 | 550-650 | D638 |

*Data provided herein is meant to show a general range for the HydroThane product lines; these properties can be tailored to meet specific values based on customer requirements.

ChronoThane®T (CT T)

Versatile and effective, Strong dimensional control through ease of manufacturability

Aliphatic Polyether-Based Urethanes

Description

· ChronoThane T is a family of aliphatic ether based polyurethane elastomers.

· These biocompatible materials possess characteristics such as low coefficient of friction, low extractables, dimensional stability, high impact resistance, and excellent tear strength.

· ChronoThane T can be tailored to meet specific Melt Flow Index ranges to suit your manufacturing or extrusion processes.

· These materials are available in hardnesses ranging from 75 Shore A to 75 Shore D.

· Pre-Processing Recommendations:

· ChronoThane T processing can be optimized by drying to a moisture content equal to or less than 0.05% by weight prior to melt processing.

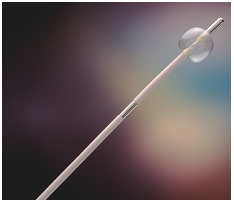

WIRE COMPONENTS

From standard sized straight and cut wire (FastLane/FastTrack) to complex wire components, Wytech should be your first call when quality and turnaround count. For over 40 years, Wytech has been an outsourcing partner of choice for medical device OEMs and contract manufacturers worldwide who require “dead-straight” quality and need delivery fast. Wytech is adept at working with any non-toxic and non-radioactive alloy, however, Wytech is particularly skilled in working with stainless steel and nitinol materials.

Corewires

Wytech offers corewires in a variety of coated and non-coated options. Moreover, Wytech is adept at assisting our customers with the development of time and temperature specifications to create the desired stiffness and pushability

· Advanced precision grinding

· Multiple tapers

· In-house heat treating

· Tip annealing

· Stress relieving

· PTFE Coatings

· Proprietary processes

· PFOA and Chromic Acid free

· Flake resistant