· Soft Tip

· Dilator Tip

· Butt Weld

· Overlap Weld

· Single/Multilumen Application

· Neck Down

· Flaring

· Close End Tip

· Radius Tip

· Taper Tip

· Braid to Non-Braid Weld

· Balloon Tip and Weld

· Marker Band Embedding/Placement

· IV Tipping

· Angle Tips

· Skiving

· Balloon Bonding

Vante® Forming & Welding Catheters

Application

· Soft Tip

· Dilator Tip

· Butt Weld

· Overlap Weld

· Single/Multilumen Application

· Neck Down

· Flaring

· Close End Tip

· Radius Tip

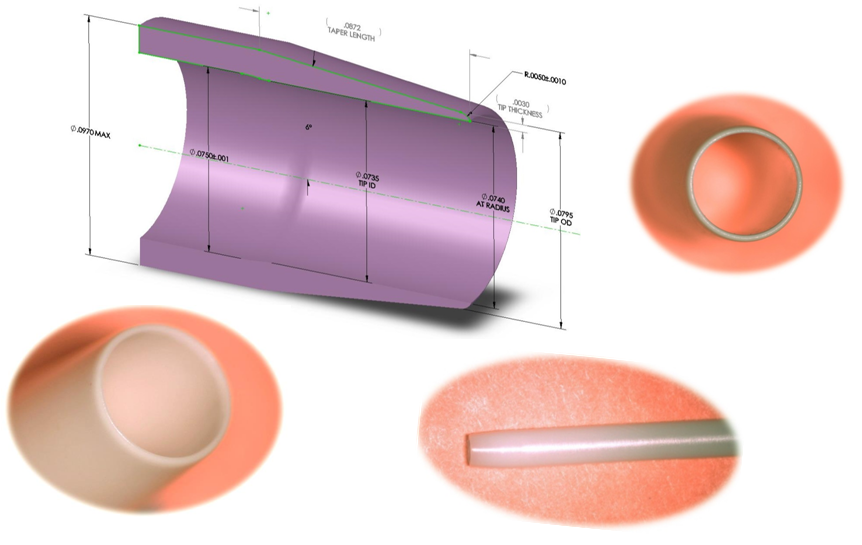

· Taper Tip

· Braid to Non-Braid Weld

· Balloon Tip and Weld

· Marker Band Embedding/Placement

· IV Tipping

· Angle Tips

· Skiving

· Balloon Bonding

TAPER/CONICAL RADIUS TIP SOFT TIP CLOSED END TIP

ANGLE TIP DILATOR TIP CVC NECKDOWN

TIP AND END FORMING SHEATH TIP IV TIPS ANGIOGRAPHIC

Vante® SAFFIRE® Thermal Forming System

The Vante® SAFFIRE® catheter manufacturing system, utilizing precision energy control and heat placement, is specifically designed for catheter manufacturing. The Vante® SAFFIRE® system consists of a model 4200 RF generator and one of two forming platforms, depending on insertion force requirements. All platforms can be teamed with a variety of tipping, welding, and forming molds creating many custom applications. The generator features a large color touch screen allowing the operator to view operating cycle parameters and temperature control. Proprietary inductive heating technology allows for higher operating temperatures while significantly extending the life of the heater.

Applications

· Taper Tips

· Radius Tips

· Soft Tips

· Soft Tips

· Closed End Tips

· Dilator Tips

· Bulbous Tips

· Flaring/Flanging

· Neck Downs

· IV Tipping

· Butt Welds

· Overlap Welds

· Braid to Non-Braid Welds

· Single/Multilumen Applications

· Split Mold Applications

· Balloon Tips and Welds

· Marker Band Embedding/placement

Features

· Closed loop temperature control

· Temperature repeatable to ± 1% up to 350°C and ± 2% for 350°C to 400°C

· Precise heat placement

· Proprietary low mass mold design

· Operator safe so there are no hot spots or pinch points

· Air cooled/no water chillers

· Solid-state circuitry

· Semi-automated

· Low friction pneumatic air cylinders and slides

· High and low insertion force platforms

· Easy to use color touch screen

· Multi-level password protection

· Multiple program parameter storage capability

· Temperature control high/low alarms with automatic disable

· Regulatory compliant, CE and cTUVus

Benefits

· Compact footprint which saves cleanroom space

· Repeatable, high quality results

· Easy to set up and validate

· Quantifiable and validatable process

· High production first pass yields

· Quick and easy tooling change

· Precision aligned tools

· Faster cycle times than previous technologies

· Supports the broadest range of applications

· Validated universal software

· Cycle counter

Vante® RUBY Thermal Forming System

The Vante® RUBY catheter manufacturing system delivers high reliability, throughput and yields along with advanced ease of use enhancements. All platforms can be teamed with a variety of tipping, welding, and forming molds creating many custom applications. RUBY functions include “Smart Mold,” a patented feature that provides the ability for parametric data to be stored in the mold module for transfer to any RUBY system automatically. This allows for auto configuration of the system. The mold assembly is designed for easy installation and removal from the platform. Process parameters are loaded quickly and reliably via system configuration sensing and software control. Digital pressure regulation provides improved pressure control and alarms when pressure tolerances are not met. Additionally, pre-assigned programs stored externally to the generator can be accessed and loaded via limited modbus capabilities.

Applications

· Taper Tips

· Radius Tips

· Soft Tips

· Closed End Tips

· Dilator Tips

· Bulbous Tips

· Flaring/Flanging

· Neck Downs

· IV Tipping

· Butt Welds

· Overlap Welds

· Braid to Non-Braid Welds

· Single/Multilumen Applications

· Split Mold Applications

· Balloon Tips and Welds

· Marker Band Embedding/placement

Features

· Smart Mold

· Digital Air Pressure Regulation

· Closed loop temperature feedback

· Temperature repeatable to ± 1% up to 350°C and ± 2% for 350°C to 425°C

· Precise heat placement

· Proprietary low mass mold design

· Operator safe so there are no hot spots or pinch points

· Air cooled/no water chillers

· Solid-state circuitry

· Semi-automated

· Low friction pneumatic air cylinders and slides

· High and low insertion force platforms

· Easy front panel programming

· Multi-level password protection

· Multiple program parameter storage capability

· Temperature monitoring with high/low alarms

· Regulatory compliant, CE and cTUVus

Benefits

· Compact footprint which saves cleanroom space

· Repeatable, high quality results

· Easy to set up and validate

· Quantifiable and validatable process

· High production first pass yields

· Quick and easy tooling change

· Precision aligned tools

· Faster cycle times than previous technologies

· Validated universal software

· Cycle counter

Vante® EMERALD Thermal Forming System

The Vante® EMERALD catheter manufacturing system is designed to support multiple part manufacturing of both small and large profile catheters. The Vante® EMERALD system consists of a model 3400 RF generator and one of several forming platforms, depending on requirements. All platforms can be teamed with a variety of tipping, welding, and forming molds creating many custom applications. A proprietary mold design and closed loop temperature control allows for precise heat placement, an especially critical feature for controlling flash and achieving quality results.

Applications

· Taper Tips

· Radius Tips

· Radius Tips

· Soft Tips

· Closed End Tips

· Neck Downs

· Butt Welds

· Overlap Welds

· Single/Multilumen Applications

· Dilator Tips

· Flaring/Flanging

Features

· Multiplex up to two platforms

· Closed loop temperature control

· Temperature repeatable to ± 1%

· Proprietary low mass mold design

· Precise heat placement

· Proprietary low mass mold design

· Operator safe so there are no hot spots or pinch points

· Air cooled/no water chillers

· Solid-state circuitry

· Semi-automated

· Low friction pneumatic air cylinders and slides

· High and low force platforms

· Easy front panel programming

· Multi-level password protection

· Multiple program parameter storage capability

· Temperature monitoring with high/low alarms

Benefits

· Ability to process up to eight parts at a time

· Higher power for larger profile parts

· Compact footprint which saves cleanroom space

· Repeatable, high quality results

· Easy to set up and validate

· Quantifiable and validatable process

· High production first pass yields

· Quick and easy tooling change

Vante® JADE Thermal Forming System

The Vante® JADE catheter manufacturing system embodies Vante’s closed loop temperature control and adds flexibility for the user to design molds and develop applications. All application design and development can be managed by the user or contracted for Vante® support. The JADE system design includes heater modules that accept glass or metal molds accommodating material sizes from 3 to 25 French. The Jade system can be utilized with a variety of tipping, welding, and forming molds creating many custom applications.Thermo plastics with melting temperatures under 320°C can be formed with the JADE. Easy to use touch screen programming with software pre-validated to regulatory requirements. Rapid, closed loop temperature controlled to within ± 2% of the target temperature.

Applications

· Taper Tips

· Radius Tips

· Soft Tips

· Soft Tips· Closed End Tips

· Neck Downs

· Butt Welds

· Overlap Welds

· Single/Multilumen Applications

· Balloon Tips and Welds

· Dilator Tips

· Flaring/Flanging

Features

· Closed loop temperature control

· Repeatable to ± 2% of target temperature

· Regulatory compliant, CE and cTUVus

· Operator safe with no hot spots or pinch points

· Easy to use color touch screen

· Multi-level password protection

· Multiple program parameter storage capability

· High/low temperature alarms with automatic disable

· Air cooled/no water chillers

· Semi-automated low friction pneumatic air cylinders and slides

· Solid-state circuitry

Benefits

· Compact footprint which saves cleanroom space

· Repeatable, high quality results

· Easy to set up and validate

· Quantifiable and validatable process

· Consistent, reliable output

· Quick and easy tooling change

Vante® TOPAZ Catheter Manufacturing System

The Vante® Topaz Catheter Manufacturing System is designed as a manufacturing system that targets low cost, low complexity applications that do not require high throughput and precision thermal profiles. System capacity is defined by the single cavity, resistive heating design that is limited by power, temperature and allowable material composition and size. Application design and development managed by user unless contracted to Vante. System design includes heater blocks that accept glass or metal mold sleeves to accommodate a range of sizes from 6 to 18 French material. Materials with melting temperatures under 230°C can be formed.

Applications

· Taper Tips

· Radius Tips

· Soft Tips

· Closed End Tips

· Dilator Tips

· Flaring· Neck Downs

· Butt Welds

· Overlap Welds

· Single/Multilumen Applications

Features

· Air cooled/ no water chillers

· Closed loop temperature control

· Operator safe - no hot spots or pinch points

· Semi-automated

· Easy front panel programing

· Low friction pneumatic air cylinders and slides

· Adjustable heat zone

· Solid state circuitry

· Temperature repeatable to ± 2%

· Multiple program storage

· Password protection

Benefits

· Compact footprint which saves cleanroom space

· Repeatable, high quality results

· Easy to set up and validate

· Quantifiable and validatable process

· Consistent Reliable Output

· Quick and easy tooling change

For a timely response, go to Online enquiry or contact us at +1 905 770 5108 or info@hngmedical.com.

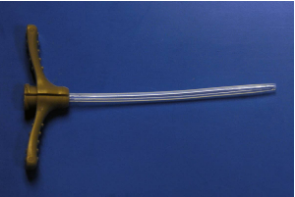

7Fr PEBAX Braid to Non-Braid Butt-Weld 9Fr PU Soft Tip Weld

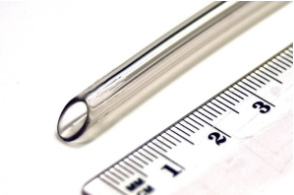

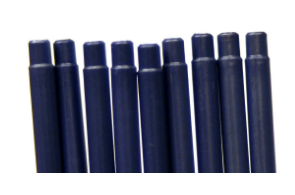

5Fr HDPE Light Purple Sheath 6Fr Dilator

10Fr FEP Flare 20Gauge FEP IV Tip

14Fr PVC Bullet Tip